On a humid afternoon in Knoxville, Tennessee, you can find the staff and volunteers at food4VOLS doing what they do best: fighting hunger and food waste in Appalachia. There's a rhythm to the work, although it's not always as smooth-running as they would like. Inadequate facilities and inefficient storage space often hinder their ability to quickly prepare large amounts of food, limiting their growth potential.

This need, coupled with their mission to combat hunger and food waste on campus, contributed to their winning Foodservice Equipment & Supplies Magazine's 2024 Kitchen Storage Makeover, sponsored by Metro. In August, several Metro staff members—including members of the marketing, customer service, and product development teams—traveled to Knoxville to install food4VOL's grand prize: over $50k worth of Metro storage and productivity solutions.

Food4VOL's mission is to help those in need and to make the world more sustainable. At Metro, we have made it our mission to make the world more organized and efficient so programs like food4VOLS can keep doing what they do best: helping people.

Here’s a closer look at our 2024 Kitchen Storage Makeover (KSM) winner and the solutions they received to make their work more efficient and productive.

Food4VOLS: No Hunger. No Waste.

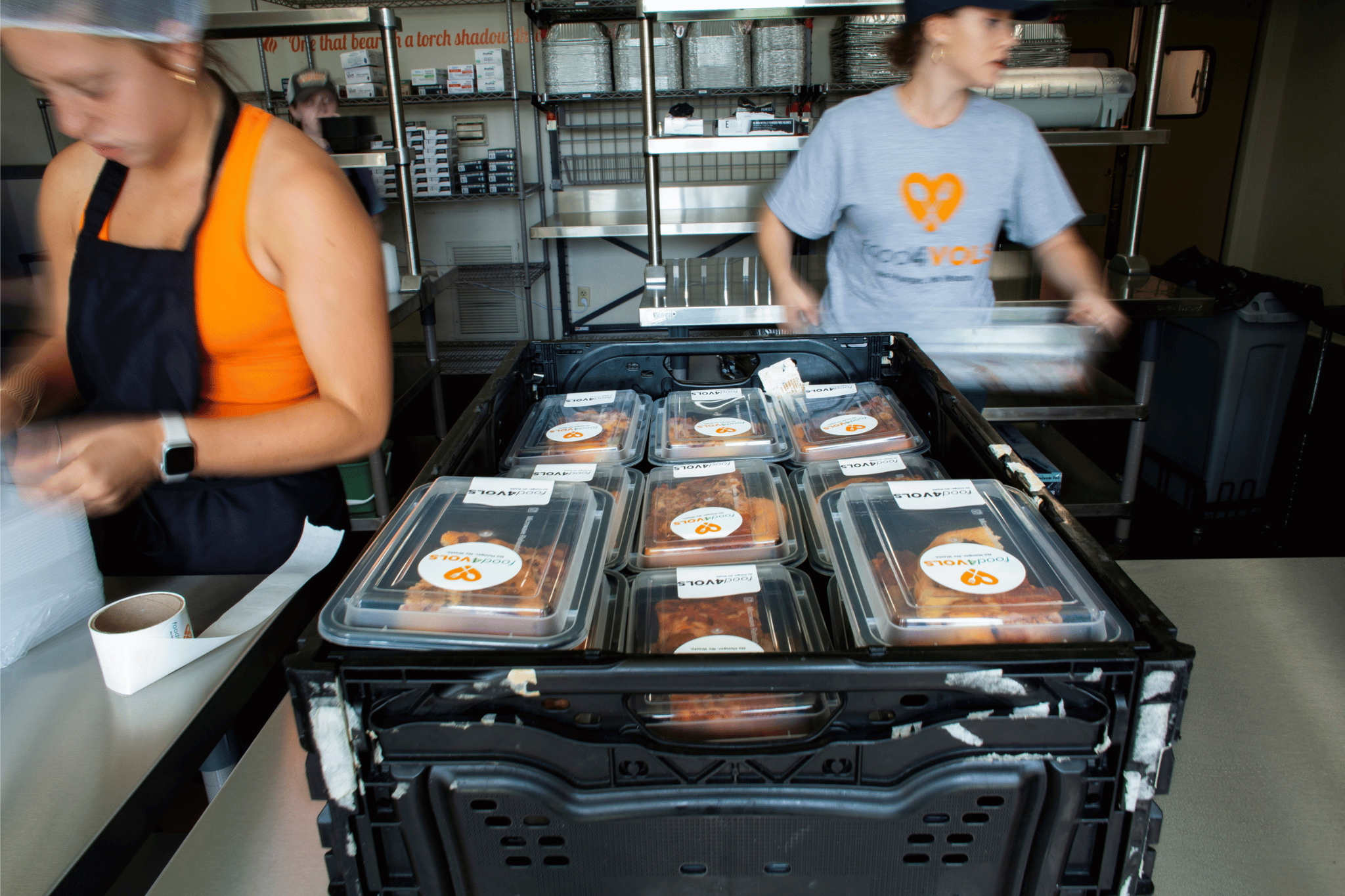

Food4VOLS is a food recovery program designed to end hunger on the University of Tennessee, Knoxville campus and the surrounding counties. Every day, dedicated volunteers collaborate with restaurants and cafes on and around campus to rescue perfectly good food that would otherwise end up in the trash. This reclaimed food is then taken to the UT Culinary Institute, where it takes on a new life as nutritionally balanced, ready-to-eat meals.

Tyler White, the food4VOLS Program Manager, developed the concept in August 2021 and has been leading the charge since then. It's a simple idea with a huge impact: reduce food waste on campus and feed those who need it most. Their work is already being recognized for its impact; Food4VOLS was recently recognized for its work and won the Tennessee Governor's Environmental Stewardship Award for material management.

Food insecurity is a significant issue affecting millions of Americans each year. Hunger doesn't discriminate—it affects students, families, and entire communities. It's that kind of problem that hides in plain sight. On college campuses, students often feel it the hardest as they struggle to balance tuition, housing, and everyday living costs. That's where programs like food4VOLS come into play, bridging the gap with a simple yet effective solution.

food4VOLS hopes to increase their food production to 600 meals per day, doubling their current output.

Fighting Food Insecurity, Waste & Inefficiencies

Since its inception, food4VOLS has done something remarkable: rescuing more than 350,000 pounds of food and preparing more than 100,000 meals for students in need. And their impact keeps growing. What began as a two-person operation cranking out 50 meals per day has increased to a team of six employees producing 300 meals daily, five days a week, with a team of student volunteers.

They show no signs of slowing down, either: the program's goal is to increase production to 600 daily meals this year, and if the past is any indicator, they'll exceed it—as long as they get the right help.

And it's not just students who benefit from this nonprofit program. In addition to the meals packaged for students in plastic ready-to-heat containers, food4VOLS also provides meals to seven charitable organizations, including rehabilitation centers and homeless shelters in four counties surrounding the university.

As food4VOLS has grown, so have the challenges. One major hurdle the program has faced is funding. While they provide a vital service to the University of Tennessee students and the community, the school does not provide funding for the program.

Additionally, they operate out of a converted house, and the layout isn't ideal for their operations.

Here's what they wrote to us in their KSM application:

Food4Vols operates out of a converted house that is now a multi-use facility. Our primary production space is a hodgepodge of laminate and stainless-steel worktables in the center of what used to be the home's living room, fireplace to boot. Our storage facilities exist in a carpeted former bedroom, and our shelving units are comprised of mismatched racks, rusted shopping carts, and folding banquet tables.

While we might not be able to solve all their funding issues, we knew we could enhance their storage, production, and transport solutions, improving their workflow and efficiency. By doing so, we knew we could help fight food insecurity within the community.

The Assessment

Once food4VOLS was named the winner of KSM 2024, the real work began—starting the assessment. Sure, the installation might get most of the fanfare, but ask any team member, and they'll tell you that the assessment is where most of the magic happens.

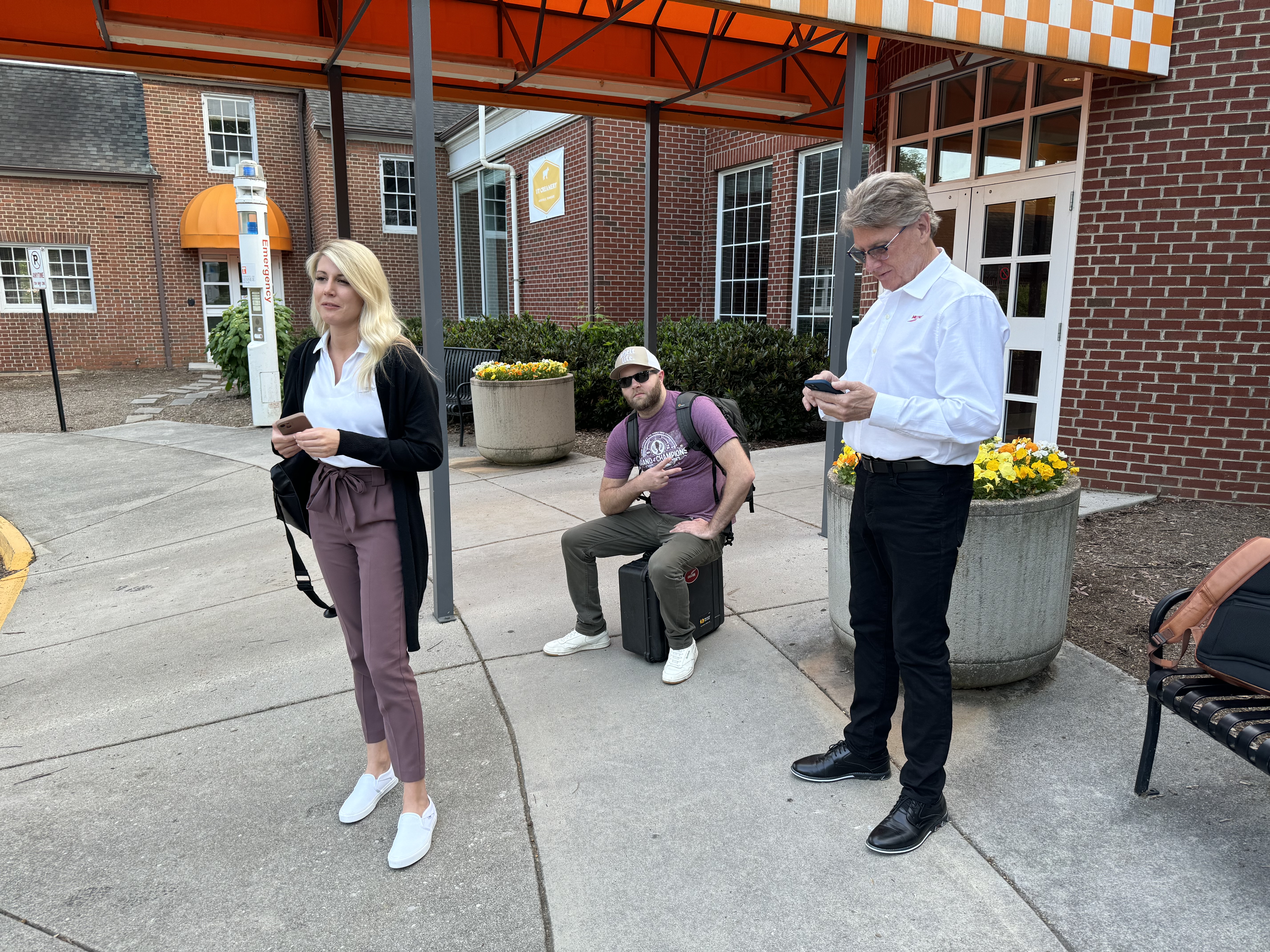

So, in early May, a few key team members hit the road (well, skies) and moseyed their way down to Knoxville, Tennessee, to start the process. They found a welcoming father-son duo and a team of student volunteers looking to improve the functionality of their space but without the resources or the know-how to do so.

"Disorganization is intimidating," reflects Gerry Kenlon, Director of Global Strategic Accounts at Metro and productivity expert. "Maybe you don't know where to start, and that's why the assessment is so vital. We identify the environment, come in with a fresh perspective, and identify solutions that you may not even realize exist."

To make the magic happen, our team had to get hands-on at the Food4VOLS facility, rolling up our sleeves and digging into the nitty-gritty of daily operations. That meant early mornings, late nights, and questioning each other's ability to properly use a tape measure.

The Metro Assessment Team after a long day at food4VOLS

The Pain Points

A Director of Creative & Brand Communications, a Director of Global Strategic Accounts, and a National Strategic Accounts Manager walk into a quaint converted house, followed by a videographer —it sounds like the start of a joke, but for the KSM team, this was [mostly] serious business.

For AJ Zambetti, Metro's Director of Creative & Brand Communications, this isn't his first rodeo. He's overseen every Kitchen Storage Makeover since he initially came up with the idea. And while seven years of KSM might sound repetitive, every year brings a unique experience with new challenges.

"We created Kitchen Storage Makeover in 2017 to showcase what we do and the benefit of our brand," said AJ. "This year was a bit different. Unlike many of our other winners, very little cooking or serving was involved. Instead, it was all about logistics, transport, and distribution efficiency."

At the end of the day, Metro's goal is to help food4VOLS achieve its goal, which is to reach at least 600 meals prepared per day. Unfortunately, their existing processes didn't allow for that. However, by uncovering their biggest pain points, our assessors were able to come up with customized solutions to help improve the efficiency of their operations.

We'll get into more of that later, but here are the biggest issues AJ and the team encountered:

- Lack of adequate storage space throughout the facility, particularly in key locations

- Limited workspace in the prep area and non-NSF-listed worktable

- Inefficient speed racks

- Improper shelving in the dish room

- Limited space in walk-ins (speed rack Tetris)

Once the team fully understood the day-to-day operations and saw for themselves what could be improved upon, it was time to brainstorm the best ways to improve their workflow and efficiency.

From Sketch to Reality

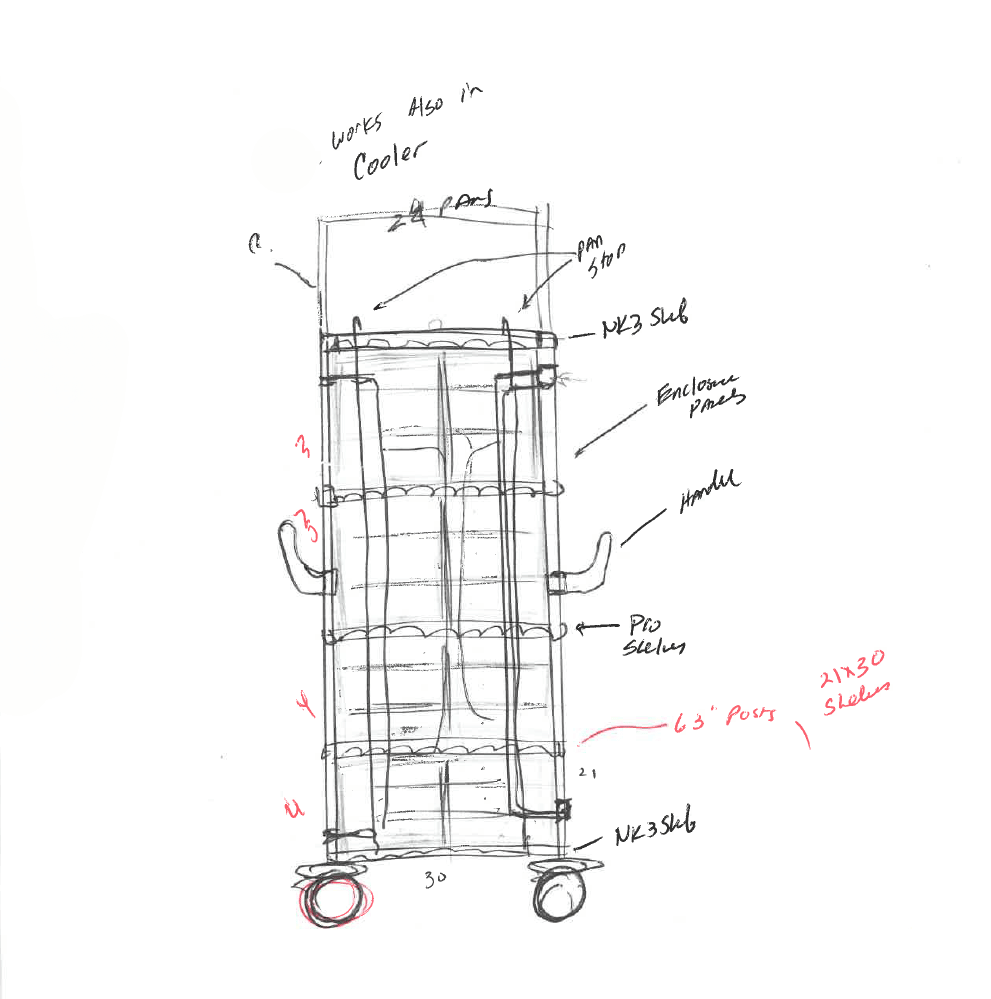

AJ Zambetti's biggest challenge for this year's KSM was food pick-up efficiency. "The amount of energy they were burning just to collect food from all over the community was wild," AJ says. "It's such a spread-out process, and it's tough for them to really dial in efficiency."

As a graphic designer by trade, AJ didn't just envision the solutions—he drew them. Quite literally, he went "back to the drawing board," time and time again, sketching out ideas to streamline food4VOLS' transport system. With his pen in hand, he mapped out the most feasible ways to simplify and speed up the process, aiming to make their operations more efficient.

One of AJ's sketches depicting his vision for what would become food4VOLS' custom food transport cart.

But that wasn't the only area that needed a rethink. Armed with the building's footprint and a clear vision, the Metro team mapped out the best solutions for each space, figuring out exactly where storage should go, how to position worktables for maximum productivity, and the smartest configurations for the walk-in cooler and freezer. Every inch mattered.

From AJ's sketchpad to the final layout, the team was committed to ensuring food4VOLS could not only meet but exceed their goals of feeding more people faster and more efficiently.

Watch Part 1 of our 2024 Kitchen Storage Makeover: the Installation.

The Install

A few short months after the assessment team flew out to Knoxville, it was time for the more physically demanding part of KSM: the installation.

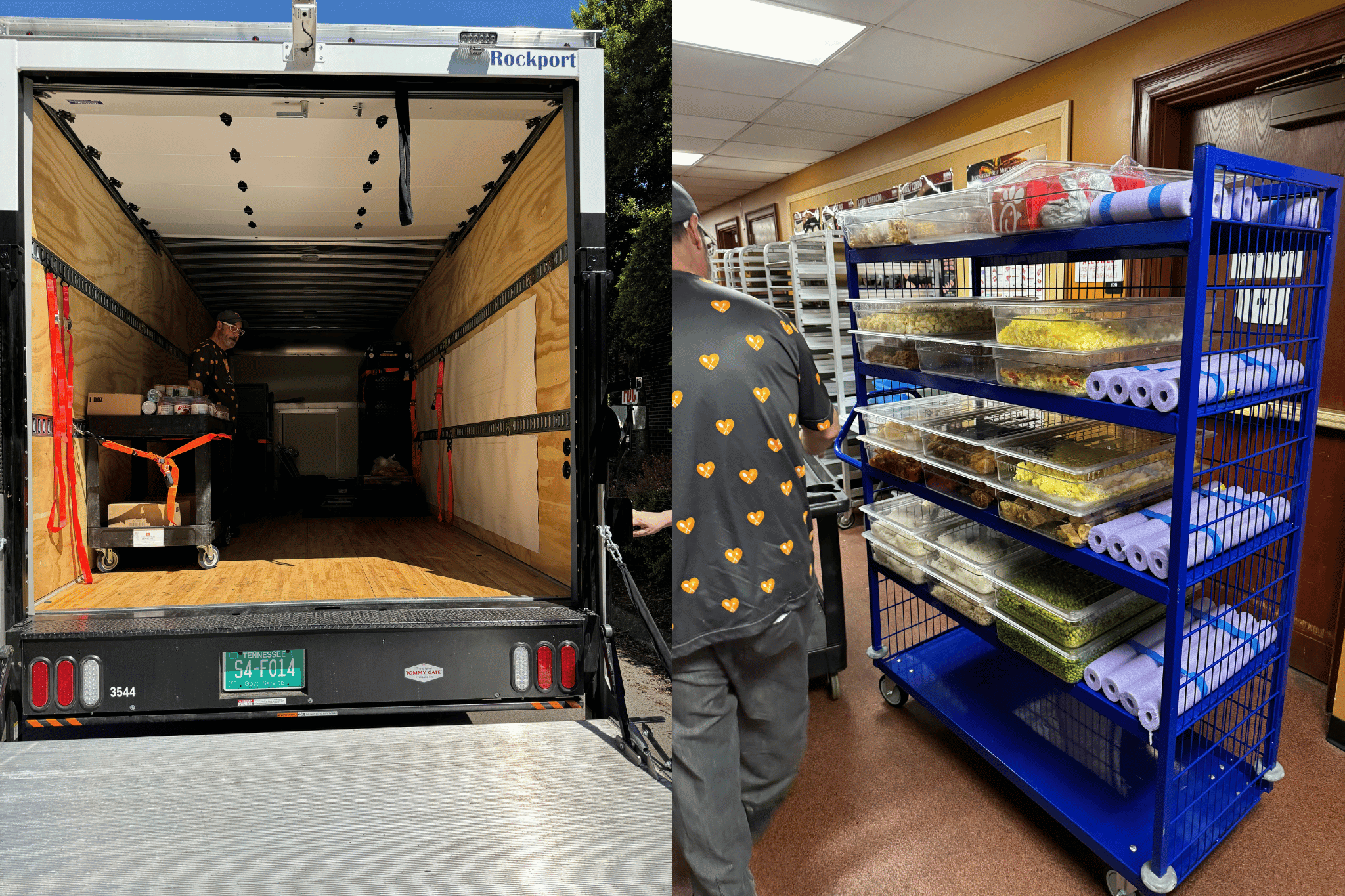

It was a warm, sunny morning when two Metro delivery trucks pulled up to the University of Tennessee's Knoxville campus. It was the start of something big for food4VOLS: after months of anticipation, the much-awaited Kitchen Storage Makeover installation day had finally arrived.

The excitement was palatable. Inside two box trucks were their grand prize: $50k worth of brand-new shelving, worktables, and custom storage solutions that would help transform this nonprofit. Today marked the beginning of a transformation that would streamline their workflow and empower them to feed even more people across campus and the surrounding communities.

Chris Wenger, Manager of Marketing Logistics, ensured the delivery process went smoothly.

From Plan to Action

Chris Wenger, Manager of Marketing Logistics, is the guy behind the curtain. He plays a major role in ensuring every KSM installation happens, overseeing all aspects of product ordering, shipment, and delivery. "Most things went according to plan," he says regarding the install. "The trucks rolled in right on time, and honestly, this was one of the easiest and cleanest to date.”

But let’s be real—no project at this scale happens without a few bumps. Before everything could be unloaded, the team ran into its first hurdle: the pallet of products was too big for the liftgate. It was a minor issue that required some quick thinking and teamwork.

Then, as assembly began, they discovered a few essential parts were missing. Unlike the weather, this was nothing to sweat about—Metro’s customer service team in Wilkes-Barre was just a call away, and the missing pieces were shipped overnight.

After seven years of Kitchen Storage Makeovers, we’ve learned to expect the unexpected, even when every detail has been meticulously planned. But if there’s one thing our team knows, it’s how to keep moving forward. A liftgate issue? No problem. Missing parts? Sorted. And now, the real magic was about to begin.

Let’s look at the transformation process room by room.

The Installation Team ready to make the magic happen.

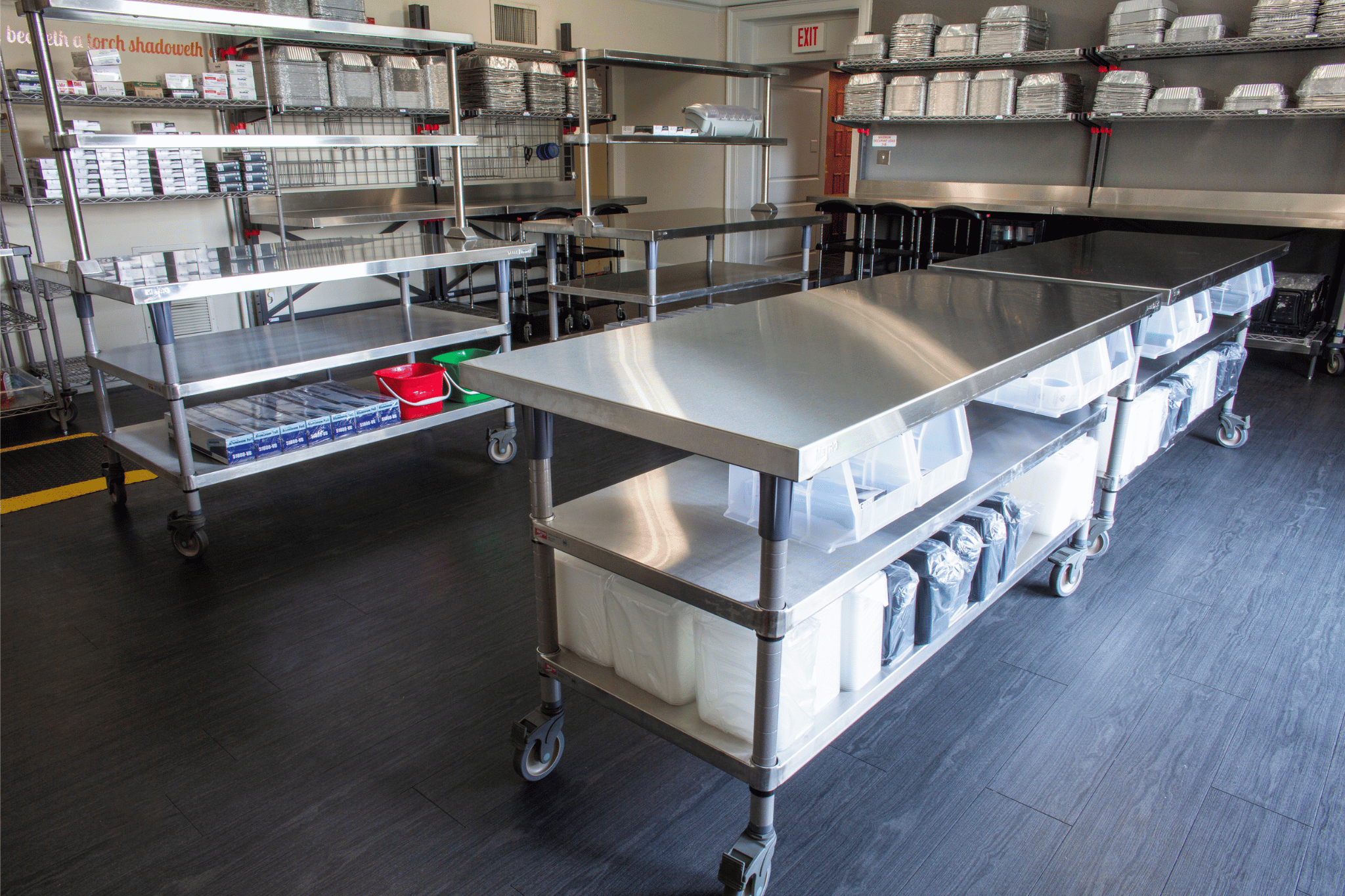

Main Prep Area

At the heart of the food4VOL’s mission lies the main prep area, a busy space where volunteers carefully package and prepare meals for the campus and community. Prior to the makeover, the space was proving to be a bit of a roadblock; they only had one main table for student volunteers to work on, which was not an efficient use of the space. It was also hindering the capacity of their production.

Before: student volunteers had one table for prepping meals.

But all that was about to change with the makeover. Every foot of this integral space was transformed with a focus on flow and functionality. We swapped the mismatched tables-turned-workstations and haphazard setups in favor of a new streamlined assembly line with purpose-built solutions designed to maximize efficiency.

The custom-engineered TableWorx stainless steel worktables, with built-in channels to hold bins, now provide the ideal stainless-steel surfaces for food prep and packaging. Unlike the previous makeshift tables, these are built for foodservice and can handle rigorous cleaning and daily abuse.

We also wanted to focus on functionality and making the most out of the space. We added more workstations by integrating TableWorx with center-mount solid stainless over-shelves to allow multiple people to work at each table.

After: multiple state-of-the-art type 304 stainless-steel workstations.

The other significant change to the main prep area was the addition of the Metro SmartLever system. We utilized cantilevered shelves to provide plenty of storage space without having posts get in the way of the work surfaces and leaving plenty of room underneath for myCart utility carts.

Inadequate storage was another pain point in this room. Volunteers had to go from room to room looking for what they needed, wasting precious time. By adding better shelving and smarter solutions where they’re needed most, essentials are now within easy reach.

Transport Truck

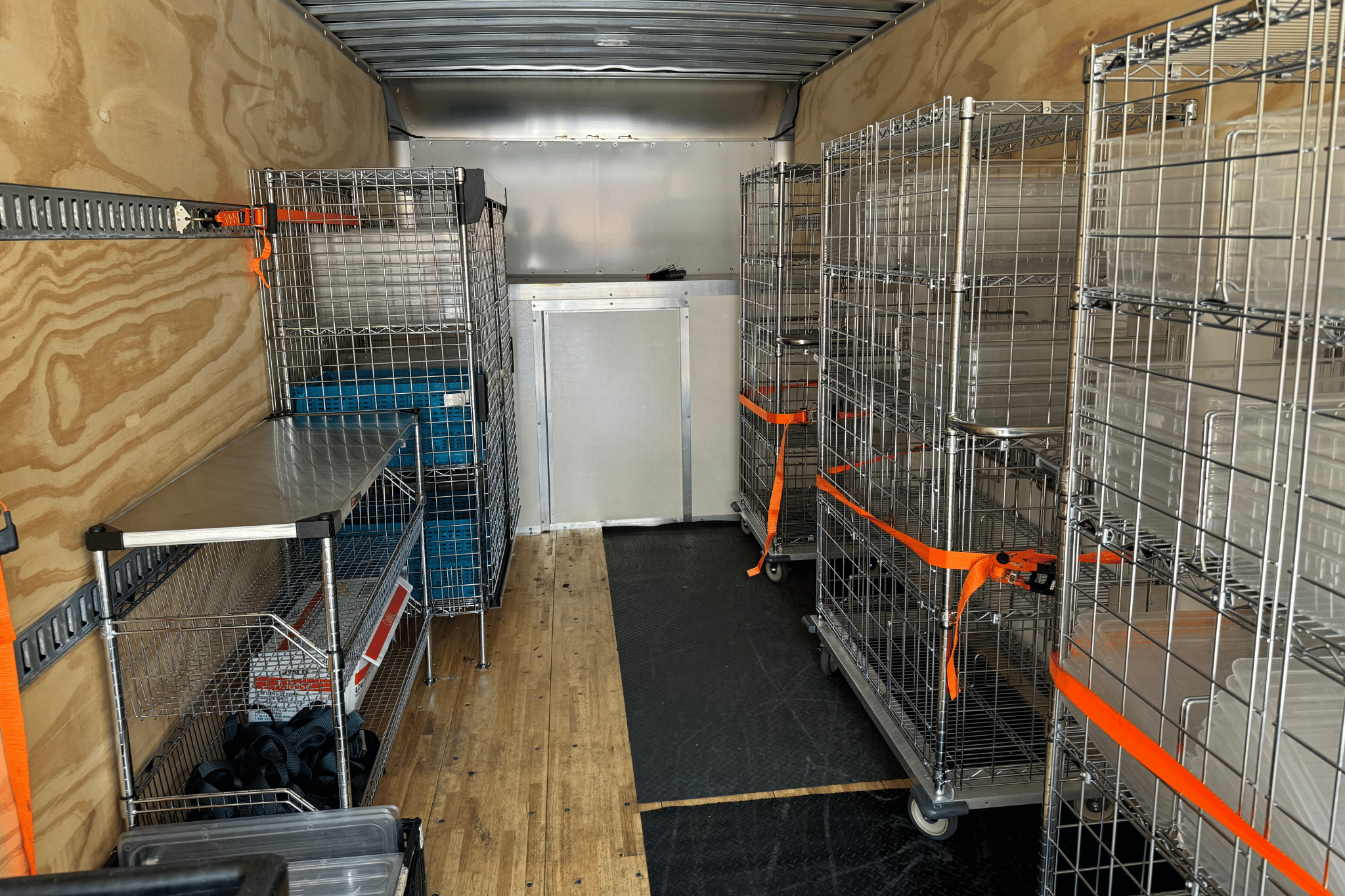

If the main prep area is the heart of food4VOLS, then the transport truck is its lifeblood: everything they collect and distribute passes through the truck. And while the makeover for this area only took the team about twenty minutes, those twenty minutes had a huge impact.

Before: a big blue cart equipped with pool noodles was the primary means of food transport on the truck.

For AJ Zambetti, this truck presented one of the toughest challenges of the project. "It’s a catch-22," AJ explains. "You want to limit the number of trips, but when the volume’s too heavy or awkward, it’s hard to manage." And he’s not kidding—the original transport method was a big blue behemoth on wheels, creatively rigged with pool noodles. Yes, pool noodles.

The solution? Custom carts swivel casters and handles on both sides for easier movement. The program’s coordinator, Andrew White, summed up the impact best: “I can do a 360 in, like, two seconds,” he said during the big reveal. “That makes my life so much easier.”

After: we outfitted their transport truck with custom transport carts, a security cage, and steel worktable with basket shelves.

In addition to the real star of the show, we also outfitted the truck with a security cage with a sliding door (a much-needed upgrade from their laundry tub setup) and added a worktable with basket storage to keep things organized, even when the truck’s in motion.

Dry Storage Area

For the dry storage room, we weren’t just thinking about today’s needs—we had our eyes on the future. With food4VOL’s mission to expand its meal production, we knew their storage solutions had to grow with them. Our goal? Maximize the space and make it accessible while also future-proofing it for the increased demand that’s sure to come.

Before: the biggest issue in the dry storage area was underutilizing vertical space.

This room saw the most impact through the utilization of vertical space. We started with a single-layer table as the main storage option for multiple Super Erecta wire shelving units. This allowed us to provide excess storage space within the same footprint.

This room also highlighted an interesting conundrum: when is too much storage simply…too much? When the team configured the shelving for this space, we ran into a rare problem: too much storage space. Normally, people assume the more the merrier when it comes to shelving, but that’s not always the case. You don’t want to fill a room with shelving units just because you can.

After: with just a few wire shelving units, we increased their storage capacity and future-proofed their space.

Instead of giving them unnecessary shelves, we took a different approach. We removed the bottom shelf from one of the units and created a “parking space” for two utility carts that food4VOLS staff use daily. These carts were always floating around without a real home. Now, they have a dedicated spot—no more hunting them down or tripping over them in tight spaces. Sometimes, less is more, and this was one of those times.

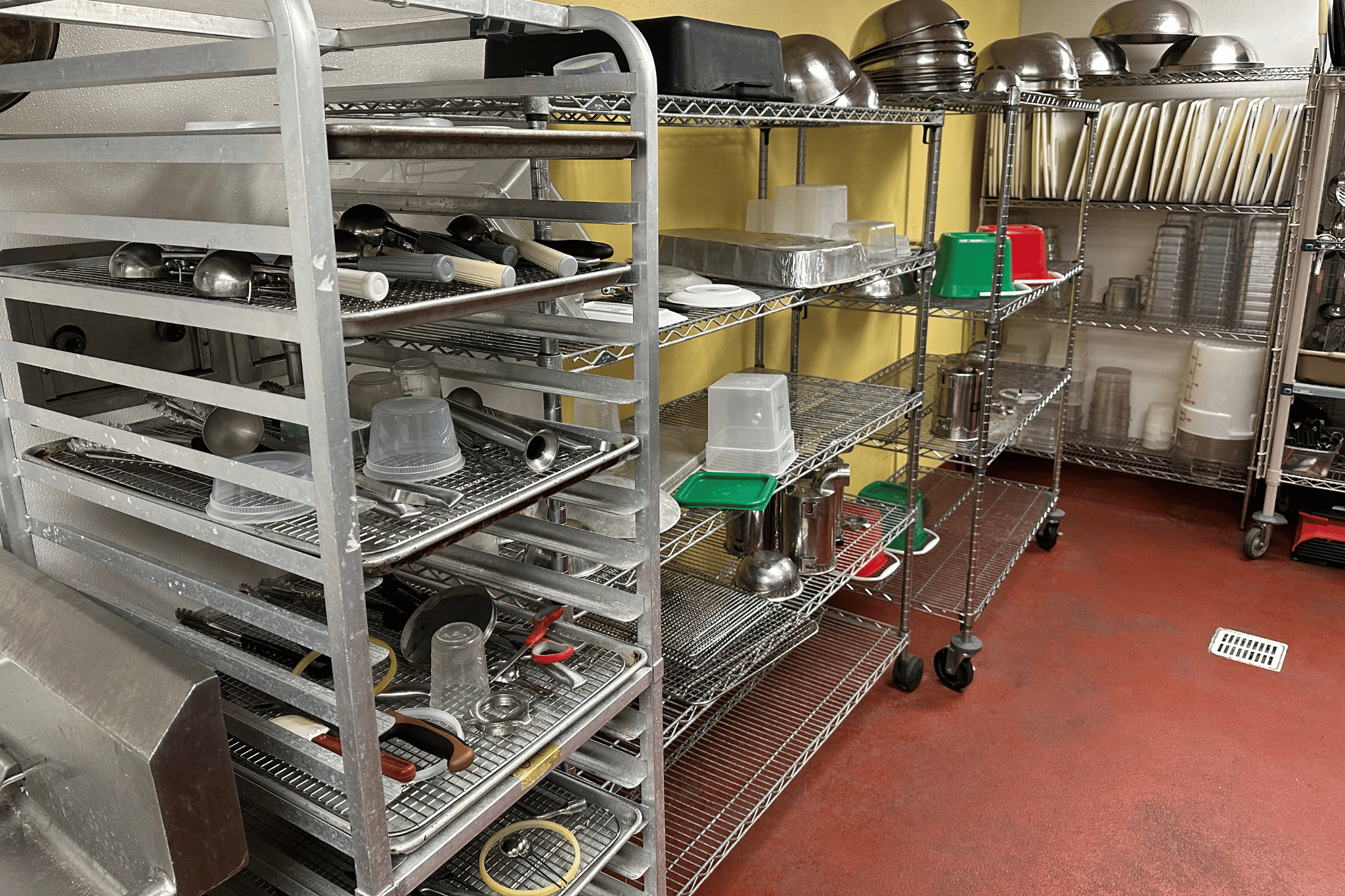

Dish Area

While the dish area had shelving, it was the wrong type. Chrome wire shelving is unsuitable for wet environments such as a dish room because it’s susceptible to rust and corrosion. If food4VOLS kept this shelving in their drying and dishwashing space, they wouldn’t see the longevity they want.

Before: chrome shelving in a dish room is a big no no!

Our mission here was simple—out with the old, in with the MetroMax. We swapped out the rust-prone shelves for polymer shelving and drying racks designed for wet areas like this one. These bad boys are built to handle the constant moisture without breaking a sweat (or, you know, rusting).

The goal for this space was to give the team enough storage space for their big items and small wares. With proper shelving and room to breathe, we could ensure that wet nesting wouldn’t be a problem for this nonprofit.

After: we set them up with MetroMax shelves and drying racks that have a lifetime warranty against corrosion.

Walk-in Cooler

The walk-in cooler needed a lot of love. Before we arrived, it was very inefficient. Their track shelving system wasn’t just ineffective—it was holding them back. The underutilized shelves were taking up valuable space needed by speed racks, and the floor track was an obstacle their carts struggled to cross over.

Before: their existing track shelving system took up valuable floor space and became an obstacle for their carts and pan racks.

So, we tore out the old track system and replaced it with a new high-density Top-Track system along the shorter wall. This opened up the floor space while maintaining the same amount of shelf space and a large active aisle. And since we went with a Top-Track unit, we eliminated the floor obstacles for the utility carts.

And that wasn’t all. We also gave food4VOLS new, more efficient racks to hold more food per unit. Our adjustable pan racks can accommodate hotel pans without bun pans. Each Metro rack can hold 24 pans, doubling their storage capacity.

By doing this, we were able to eliminate a lot of the “cooler clutter” by reducing the number of pan racks while increasing capacity. With a more efficient cooler layout, food4VOLS can fit more food within the same footprint, allowing them to grow and reach their goal of 600+ meals per day.

After: by reconfiguring their space and giving them the right pan racks, we significantly reduced their cooler clutter.

Walk-in Freezer

Last but not least, we gave food4VOLS a freezer facelift, focusing on both organization and access. To keep things organized and accessible, we utilized S-hooks with our MetroMax Q shelving system to maintain open access to the corners and avoid double posts.

Before: the unconventional bread rack storage system was difficult to maneuver around.

During our assessment, we discovered that food4VOLS had been relying on a rather unconventional method of storage in the freezer: an old bread rack. While unconventional, it was the best way for them to store bagged products at the time. However, it was hard to move and heavy, so we knew we could give them a better option.

We utilized a MetroMax Q bread rack system that would allow food4VOLS to use their bread racks but have significantly easier access to the products. If they need something that’s stored on the bottom rack, they don’t have to move all the other racks to get to it.

Now, everything has a place, and nothing is left in the middle of the floor.

After: by improving the storage in the freezer, we eliminated the clutter in the middle of the floor.

A Lasting Impact

Food4VOLS’ efforts to end hunger and reduce food waste in Knoxville and surrounding areas continue to make a real difference in the lives of students and community members alike. While the Metro team only spent three days installing our new solutions, we know that the impact of these changes will last a long time.

We are proud to have improved their facility and help pave the way for the next phase of growth. With improved storage, workflow, and transport solutions, food4VOLS is now more efficient and ready to meet its goal of preparing 600 meals a day.

“We knew we were doing an ok job…but we didn’t know how to get to the next level,” Tyler White reflects after the big reveal. “Having the Metro team come in and show us what we should be using and how to make our lives easier has been quite eye-opening for our whole process.”

At Metro, we’re proud to play a part in supporting programs like food4VOLS, whose mission to create a more sustainable and hunger-free world inspires us all. Stay tuned for the next call to entry for the 2025 Kitchen Storage Makeover, and let’s continue working together to make a difference—one meal at a time.

Everyone enjoyed their experience helping food4VOLS, and we look forward to KSM 2025.