In electronics manufacturing, precision and reliability are of the utmost importance. Every circuit board, microchip, and connector plays an integral role in the functionality and performance of the final product. Therefore, manufacturers must adhere to specific ESD (electrostatic discharge) protocols to maintain a safe working environment and guarantee product quality.

Nothing is more frustrating (and cost-prohibitive) than spending time and money manufacturing electronic devices only to find out they don’t work because of a damaged component. Even worse is when a product goes to an end user and fails to work properly due to an ESD issue. No engineer wants their product to make it into the field and be a “dud.”

ESD may not always be perceptible to humans, but it poses a significant threat to electronic components. Even the slightest discharge can cause significant damage. For example, while 100 volts is the typical threshold in most settings, as little as 10 volts can damage microelectronics to some degree. For some perspective, it takes close to 3000 volts to be perceptible to a human, and up to 30k volts can be generated by just walking across a floor.

It's also important to note that damage does not always cause immediate failure. In many instances, ESD impedes performance in the field and/or leads to a future failure in the field. Since the repercussions of such damage can be unpredictable, mitigating ESD risks is non-negotiable.

At Metro, we understand the importance of ESD safety for Electronic Manufacturing Services (EMS). That's why we offer a full range of effective ESD management solutions to ensure a safe working environment and uphold uncompromising product quality standards.

Learn more about our ESD and PCB storage solutions.

What is ESD, and How Does it Affect Electronics?

ESD refers to a typically invisible and sudden discharge of electrical current. ESD typically occurs when two objects close to one another create a highly charged electrostatic field.

Before an electrostatic discharge event occurs, an electron imbalance on the material's surface causes an electrostatic charge to build. Several events can produce this charge, such as shoes scuffing against a surface or rubbing certain materials together. The buildup of electrical charge leads to one surface gaining electrons, resulting in a negative charge, while the other loses electrons, resulting in a positive charge. The electrical charge is brought back into balance during the ESD event by transferring electrons via current. (Source)

One of the biggest dangers of ESD is that it can occur at almost any stage of the manufacturing process, and because it’s “invisible,” it can happen unknowingly. Any static buildup can damage electronic components such as printed circuit boards (PCBs), impacting functionality and creating long-term problems.

In addition to causing physical damage, ESD can create a logistical nightmare. Static charges can affect everything from delays in manufacturing and delivery to the equipment involved with the event. We often think of how static discharge can physically damage circuitry. However, it can also cause issues with measurement devices and the performance of precision robotics (e.g., autonomous robots in distribution centers). Manufacturers must prioritize ESD safety and ensure their workstations are static-safe to avoid technical and practical complications resulting in financial loss.

How To Prevent ESD in an Electronics Manufacturing Environment

Since internal damage from ESD is not always visible but can lead to shortened component lifespans and premature failure, prevention is key. All electrical components should only be handled in an ESD-protected area (EPA) where electrostatic fields and voltages are at low levels.

To prevent the generation and accumulation of ESD, it's essential to minimize or eliminate sources of static electricity. This can be achieved by using materials that do not generate or hold static charges, such as conductive or dissipative plastics, metals, or fabrics.

Grounding yourself and your equipment is an important method to prevent ESD damage. This process involves connecting all electrically conductive and dissipative items in the workplace to ground with a low electric potential, such as the floor. Ground provides a point of low electrical potential that enables areas of high electrical potential to funnel through, allowing residual current or buildup to escape. It is important to note that the floor isn’t automatically grounded.

Metro’s Electronics Storage Solutions

At Metro, we carry various ESD products that help eliminate the risk of ESD damage by preventing electrical charge buildup during manufacturing and storage. Our ESD solutions can be used for semiconductor manufacturing, PCB manufacturing, PCB and electronics assembly/handling, battery manufacturing, and more.

ESD Tray Transport Racks: PCB Handling Carts

When working with circuit boards, SMT components, and other sensitive electronics, it's important to handle them carefully. Metro’s ESD-safe electronics tray transport racks have been designed to maximize productivity and safely store and transport sensitive components during PCB manufacturing and electronics assembly/handling.

Each PCB cart supports ESD protection through multiple failsafes, with five points of electrical redundancy between the rack and floor: a drag chain, ESD-safe casters, conductive split sleeves, and grounding points, ensure your materials remain continuously protected from static discharge.

ESD-safe transport racks are available in side-load, front-load, and half-height options to meet the needs of your facility. Full-height end-load and side-load options can securely hold up to 38 trays, while the half-height tray transport cart can hold up to 20. All cart options can be purchased with or without trays and other optional accessories, including inlays, dry-erase labels, and indicator slides for work-in-process tracking.

Benefits and key features:

- Offers permanent ESD protection for sensitive electronic parts.

- Carts, trays, and tray contents can be sorted & categorized according to product type, application, or dedicated to a specific production line.

- Full ESD Protection: Meets ANSI/ESD S20.20-2021 compliance with redundant grounding systems.

- ESD-Safe Casters: Swivel casters, two with brakes, for controlled mobility with static protection.

- Drag Chain Included: Provides a dedicated discharge path to maintain ground continuity.

- Conductive Split Sleeves: Located throughout the assembly to dissipate charge effectively and provide product protection.

- Tray Stops Included: Secure trays during transport to prevent shifting or accidental removal.

- Conductive Label Holders: Enable proper identification while maintaining an ESD-safe environment.

Metro ESD-Safe Electronics Trays

Designed for use with the Metro ESD Safe Tray Transport System, these ESD-safe storage and transport trays are made from a statically dissipative thermoset material, offering premium ESD protection for electronic components. In addition to providing optimal conductivity and reliable protection for static-sensitive components, these ESD trays also maintain the structural integrity needed for demanding environments, including transport across various locations.

With dual stacking and nesting capabilities, Metro ESD Safe Trays are designed to maximize space when in use and minimize storage footprint when not. Optional anti-slip inlays add an extra layer of security, while reusable dry-erase labels and slide indicators support efficient work-in-process tracking and clear part identification.

Key features:

- ESD Safe: Statically dissipative construction meets ANSI/ESD S20.20- 2021 standards.

- Space-Optimizing Design: The trays nest for convenient storage when not in use; they rotate 180° to stack securely, maximizing inside clearance.

- Improved Workflow Visibility: Dry-erase labels and WIP slide indicators are available (sold separately).

- Multiple Grip & Label Points: Built-in for ergonomic handling and flexible racking.

- Optional Inlays: Standard and premium textured anti-slip inlays are available to enhance grip and thermal resistance.

ESD Tray Inlays

Optional ESD tray inlays can be used with Metro ESD-safe electronics trays for maximum protection. In addition to providing ESD protection, the inlay surface provides grip, ensuring your PCBs and other components don’t slide around on the hard plastic surface.

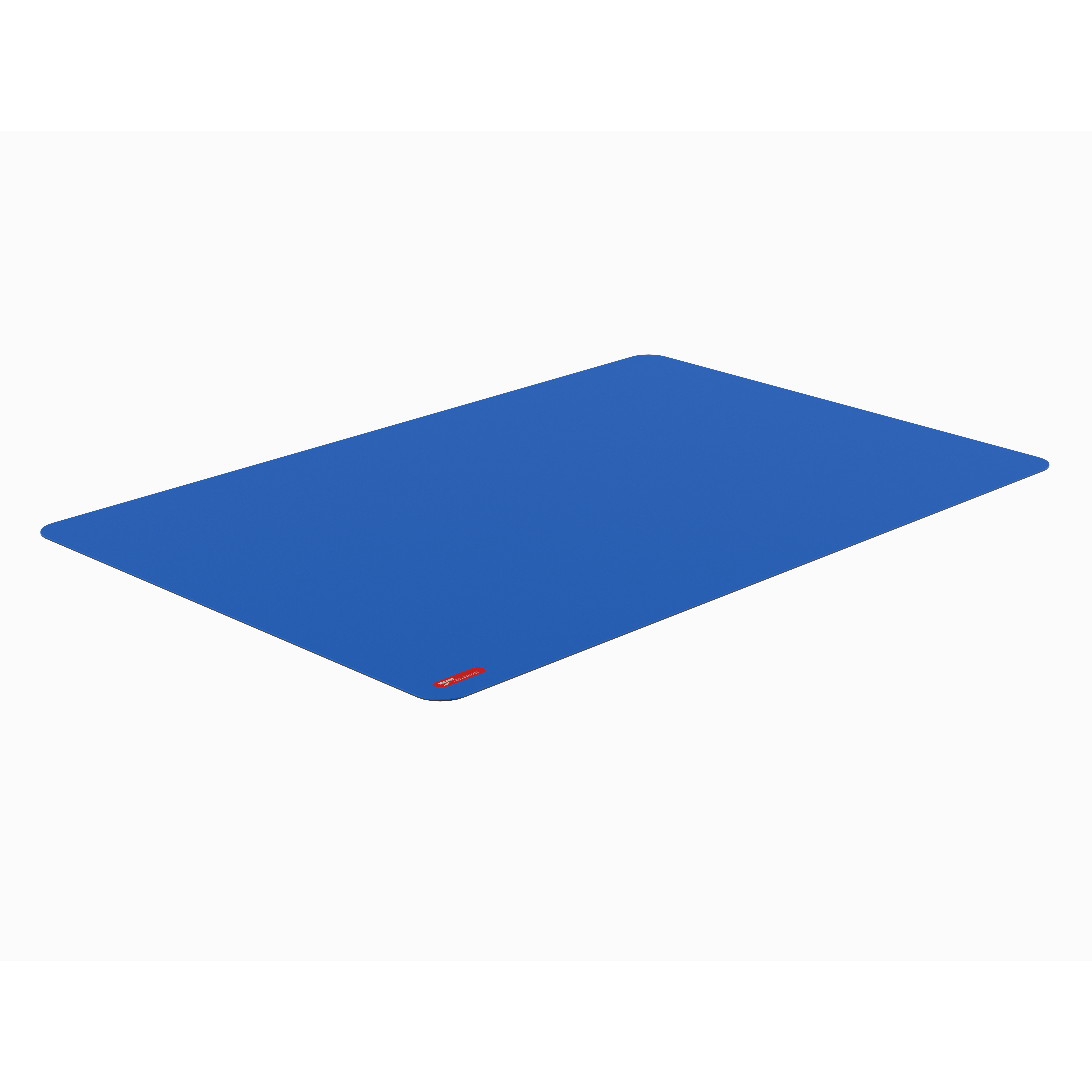

Premium inlay: Our premium inlay option also offers superior resistance to heat, abrasions, and chemicals. The soft, dissipative top layer is ideal for soldering and assembly areas. Our premium ESD inlays have the option of being both dissipative and conductive. For a dissipative solution, place the mat on the tray with the blue side up. For a conductive solution, face the black side out.

Economy inlay: Our economy option also provides static dissipative ESD protection and a cushioned surface for PCB transport. The economy tray should not be used in soldering and assembly applications. Unlike our premium inlays, these are just dissipative.

ESD Cart Covers

We carry ESD Cart Covers for our ESD-safe tray transport racks to provide extra protection when storing or transporting PCBs and SMT components. The durable cover material is conductive on the outside and dissipative on the inside, with a brass zippered front flap and side paperwork pouch. Cart covers are especially useful when transporting ESD-sensitive materials through a non-ESD location within the production facility or when storing/staging products overnight.

Metro Shelving Tote Boxes

Proper storage and organization are key elements to maintaining an EPA. We carry storage totes made from electrically conductive and electrically dissipative materials, so you can choose the right product for your electronic parts handling requirements.

Our ESD-safe tote boxes come in two colors for easy identifications:

Black — Shelving tote boxes made from a conductive polypropylene-base material. This material contains a carbon additive to provide an electrically conductive path through the material and has a surface resistivity of less than 1 x 10 5 ohms/sq. Our conductive shelving tote boxes are black in color.

Blue— Shelving tote boxes made from a static dissipative polypropylene-base material. This material has a surface resistivity of more than 1 x 10 5 ohms/sq. and less than 1 x 1012 ohms/sq. Our dissipative shelving tote boxes are blue.

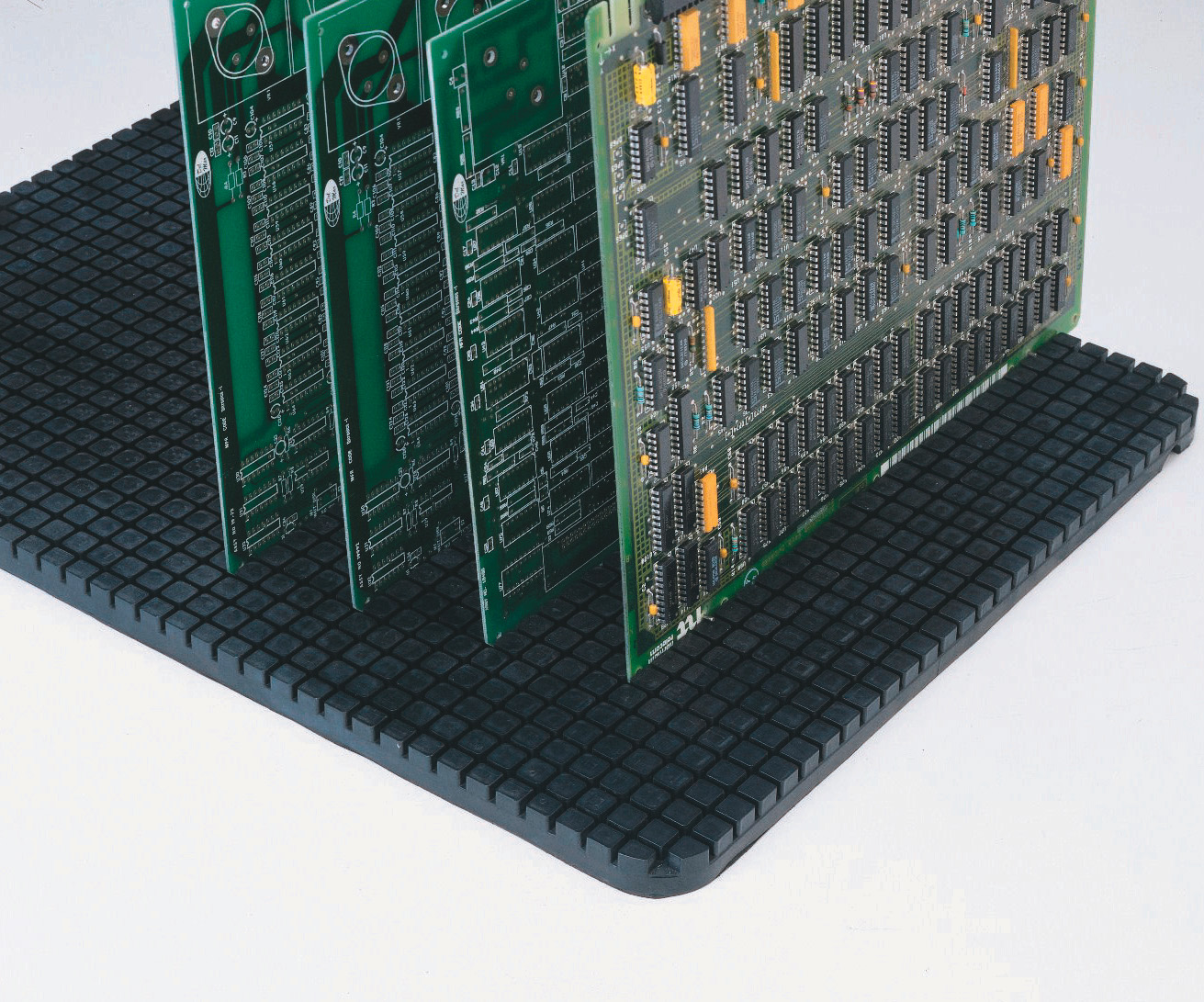

PCB Grid Boards

PCB Grid Boards are an optional accessory for standard Metro totes to maximize storage density within the containers. These inserts provide a pattern of slots where boards can be captured by the bottom edge, allowing PCBs to be stored vertically. PCB Grid Boards are available in conductive and static dissipative materials to fit the TB91000, TB92000, and TB93000 series footprints.

Kitting Carts/Tote Box Racks

Metro Tote Racks (PT Trucks for PCB Carriers) efficiently handle totes, PCB carriers, trays, or other material handling containers. With mobile kit carts, boards and other electronic components are kept safe during the manufacturing or assembling process.

Metro Super Erecta PCB handling carts are available in many configurations, including adjustable or fixed width. You can also choose from single-bay, double-bay, and triple-bay options with 2-brake and 2-swivel casters in your choice of resilient rubber or polyurethane.

For electronics manufacturing operations, tote racks can be made conductive with the addition of ESD casters and/or the use of drag chain ESD-DC12 in conjunction with GCB16S.

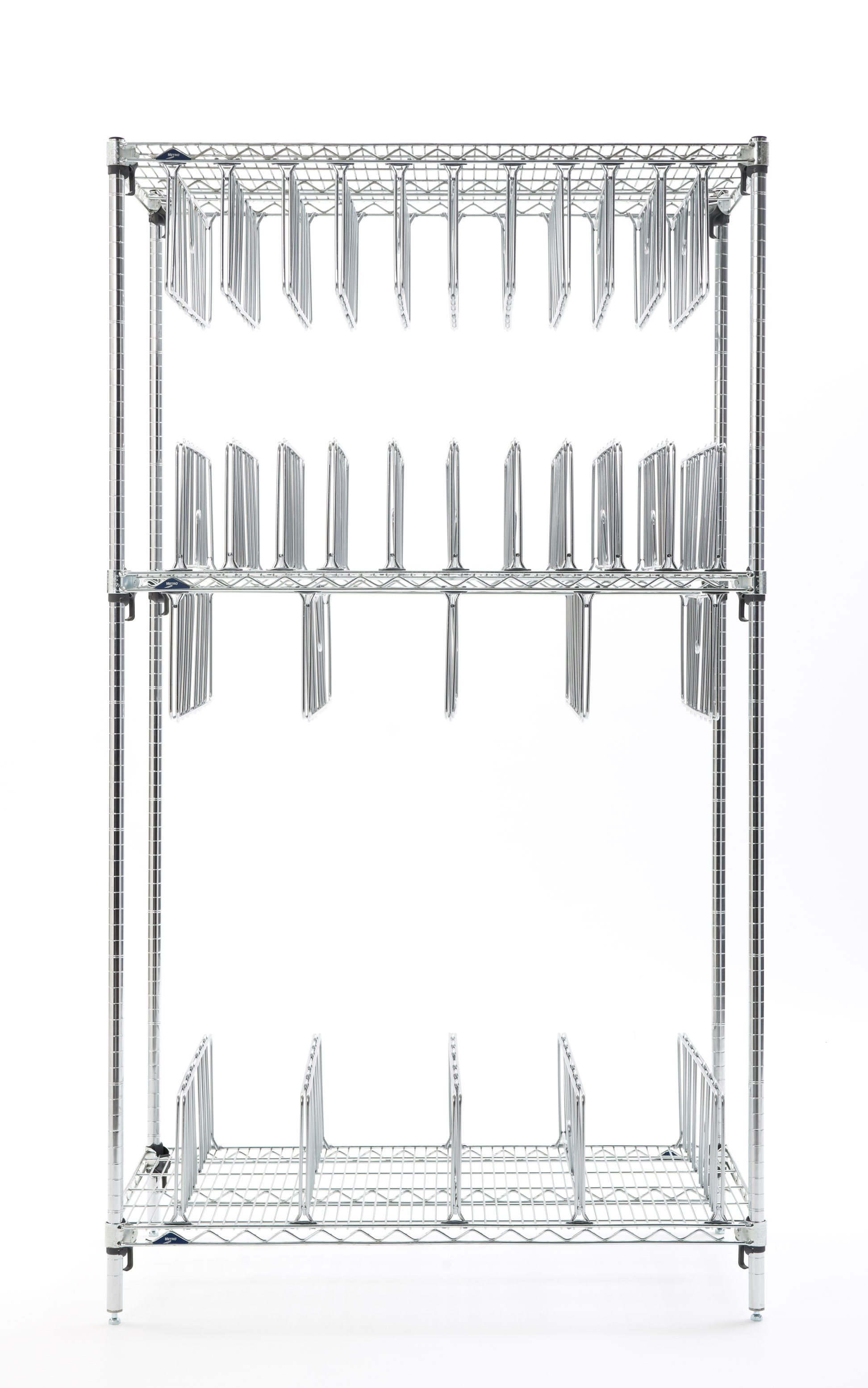

ESD Safe Super Erecta Shelving

For storage in static-sensitive environments, Metro ESD-safe Super Erecta shelving units combine the benefits of Metro wire shelving with added electrostatic discharge protection. Built with electronics manufacturing, PCB assembly, semiconductor operations, and cleanroom applications in mind, this durable ESD rack delivers secure, conductive storage for static-sensitive components and materials.

Our ESD-safe shelving is available in mobile and stationary preconfigured units for easy ordering. Each rack includes five chrome wire shelves designed to promote airflow and reduce dust and particulate buildup, helping maintain a cleaner, more controlled workspace. Chrome-plated steel posts and 9985-ESD conductive split sleeves create a continuous conductive path throughout the rack, ensuring consistent protection against electrostatic discharge.

Mobile ESD racks include two conductive swivel casters, two conductive brake casters, and a conductive drag chain maintain ground contact during transport. Stationary units come with leveling feet to ensure the rack remains stable and grounded during use in electronics assembly areas, cleanrooms, or ESD-protected zones.

Benefits and features:

- Shelves adjust in 1-inch increments for flexible configuration

- Open-wire design provides excellent visibility and quick access to stored components

- Conductive split sleeves ensure consistent conductivity

SMT Reel Shelves

Many electronics manufacturing industries utilize surface-mount technology (SMT) to mount electrical components directly onto the surface of a printed circuit board. During the pick-and place process, the components are often delivered to the production line wound on reels. The pick-and-place machines remove the parts from the tapes and place them on the PCB.

Metro’s preconfigured SMT component reel shelving offers an efficient method of storing and transporting standard-size reels. Built on the same durable Super Erecta platform as our ESD wire racks, these racks combines high-density reel storage with complete electrostatic discharge protection for static-sensitive materials in cleanroom and controlled production environments.

Options are available to accommodate 13-inch to 15-inch diameter and 7-inch diameter component reels. Each shelf can hold up to (15) 13-inch to 15-inch diameter reels or (78) 7-inch diameter reels, optimizing storage density for SMT line replenishment or kitting operations. The open-wire design supports airflow and visibility, minimizing particulate buildup and ensuring clean, organized access to components in ESD-protected areas.

Reel shelving is available in both mobile and stationary units. Mobile reel shelving units include eavy-duty conductive casters (2 brake casters and 2 swivel casters) and a conductive drag chain to maintain consistent grounding across movement surfaces while providing smooth mobility.

Benefits and features:

- 15 reel capacity for 13" (330mm) — 15" (381mm) reels*; 78 reel capacity for 7" (178mm) reels

- Can be configured and reconfigured to meet your exact needs

- Integrates with standard SES components

- Conductive with the use of aluminum or polymer conductive split sleeves

ESD-Safe Wire Utility Carts

Metro ESD-safe utility carts provide a safe and durable way to transport static-sensitive materials, tools, and components in electronics manufacturing facilities, cleanrooms, and other static-controlled environemnts. Built on the same modular Super Erecta platform as our wire shelving, these wire utility carts combine mobility, strength, durability, and ESD protection to provide unmatched performance.

Each cart features open-wire shelves that promote airflow and minimize particulate buildup, supporting clean and controlled workspaces. Conductivity is achieved through its metal construction, 9985-ESD conductive split sleeves, and a grounding system that includes a drag chain, two conductive brake casters, and two conductive swivel casters. Together, these components maintain full grounding during transport for consistent static control and optimal ESD protection.

ESD utility carts are available in chrome and stainless steel options. Each cart features ergonomic one-piece handles on both sides for easy maneuverability. Adjustable shelf heights in 1-inch increments allow users to configure carts for a wide range of transport tasks.

Chrome ESD Utility Carts

- Provide versatile, cost-effective mobility for general electronics manufacturing, assembly, and component handling.

- Ideal for transporting trays, bins, and test equipment between workstations or cleanroom zones while maintaining a grounded conductive path.

- Features 2 open-wire, drop mat chrome shelves.

- Available in two sizes: 18x36 and 24x48

Stainless Steel ESD Utility Carts

- Designed for FOUP and SMIF transport in semiconductor fabrication and wafer-handling applications where increased corrosion resistance and cleanroom compatibility are top concerns.

- Stainless steel can withstand frequent cleaning, harsh environments, and chemical exposure while maintaining full ESD protection.

- Features 2 open-wire shelves with 4" stainless steel ledges help secure products during movement.

Stencil Racks

Stenciling is the process of taking a raw board and printing (stenciling) the pathways. This process utilizes metal stencils (usually a thin sheet of stainless steel) with laser-cut openings and solder paste to attach surface-mounted components to a circuit board. Once the components are placed, the board goes into an oven, which melts the solder and seals the connection.

Metro’s SMT Stencil Frame Rack allows you to create a compartmentalized stencil storage solution utilizing the Metro Super Erecta Shelving System. SMT stencil racks are available in chrome or Type 304 stainless steel and can be made conductive with the use of conductive split sleeves and 5MESD conductive casters for mobile applications.

Electronics Casters

Metro’s electrically conducive caster wheels fit Super Erecta Shelf posts to create mobile units like shelf carts. We carry conductive stem casters and conductive stem casters with non-marking wheel treads, both of which are available with optional foot-operated brakes.

These casters are designed to prevent electrostatic discharge in ESD-safe environments by conducting static electricity out of the cart, through the wheels, and into the conductive floor. If you need to transport sensitive electronic components like circuit boards, using conductive casters in conjunction with aluminum split sleeves and a grounding cable ensure that mobile units are properly grounded to ESD floor surfaces.

We recommend using both a drag chain and ESD caster for redundant paths for the current to travel to ground, thus maximizing ESD protection.

Ensure You Have a Safe Working Environment with Metro’s ESD and PCB Solutions

According to industry experts, product losses due to electrostatic discharge (ESD) are estimated to range from 8% to 33%. Even at the lowest estimate, this figure is still too high for something that can be better avoided, especially considering the demand for PCBs and other components for the growing EMS market.

Manufacturing engineers can take many steps to limit their direct involvement in ESD damage, such as wrist straps, heel straps, shoe covers, and anti-static clothing. But it is also important to consider environmental solutions, particularly related to storage and transport.

At Metro, technological advancements are at the forefront of our product designs. We offer cutting-edge smart solutions for maintaining a safe environment when working with PCBs, hard drives, sub-assemblies, and other sensitive electronic components.

Ready to learn more about how we can help you build an ESD-safe environment? Visit our website to shop all Metro electronics solutions.