Storage plays an important role in keeping operations efficient, safe, and organized across every industry. Whether in a restaurant, hospital, laboratory, grocery store, or manufacturing facility, shelving directly affects workflow, cleanliness, and long-term performance.

Because different environments place very different demands on storage equipment, selecting shelving made from the right material is essential.

Moisture, chemicals, temperature changes, and heavy use all affect the durability and overall performance of any given shelving unit. Some materials are better suited for dry, controlled areas, while others are built to handle more extreme environments, such as

Heavy-duty plastic shelving offers the best of both worlds.

In this guide, we’ll cover everything you need to know about plastic shelving for commercial use, including how it compares to wire shelving, the types available, and the best applications. We’ll also highlight key considerations when choosing a commercial-grade polymer system and provide an overview of MetroMax heavy-duty plastic shelving to help you choose the best storage solution for your application.

For a more complete overview of shelving, check out our Commercial Shelving Buying Guide, which covers the major shelving types.

Learn about commercial plastic shelving:

- What is Heavy-Duty Plastic Shelving?

- The Benefits of Plastic Shelving

- Plastic Shelving vs. Wire Shelving

- Key Considerations for Plastic Shelving

- Types of Plastic Shelving Systems

- MetroMax Heavy-Duty Plastic Shelving Systems

- Applications for Heavy-Duty Plastic Shelving

- FAQs About Plastic Shelving

What is Heavy-Duty Plastic Shelving?

Heavy-duty plastic shelving, sometimes referred to as polymer shelving, is a commercial storage solution made from durable, high-strength polymers (plastic) rather than traditional metal. While plastic composite shelving can be made from various plastics, depending on the manufacturer, commercial and industrial-grade systems may use polypropylene, reinforced nylons, and polyesters. These engineered polymers provide durability, stability, and resistance to moisture and chemicals.

Of course, not all plastic shelving performs the same. Materials and design are two factors that influence performance and set heavy-duty, industrial-grade plastic shelving apart from home storage systems commonly found in garages, closets, or basements. Consumer plastic shelves designed for home use are lightweight and intended for low-demand environments, whereas commercial and industrial plastic shelving is built to support heavier loads, withstand frequent cleaning, and maintain structural integrity in harsh or highly regulated environments. These systems feature reinforced frames, corrosion-proof components, and smooth, non-porous surfaces suitable for foodservice, healthcare, laboratory, and cold-storage applications.

Heavy-duty systems such as MetroMax are engineered specifically for high-performance commercial use. They maintain stability under heavy loads, resist corrosion, and meet NSF requirements for use in all environments. Their design and materials allow them to perform reliably in settings where traditional wire or metal shelving may fall short.

MetroMax is the only no-rust shelving that is guaranteed never to collapse.

The Benefits of Plastic Shelving

Heavy-duty plastic shelving offers many performance advantages, making it a preferred choice for demanding environments across all industries. Because the industrial-grade polymer materials resist moisture, chemicals, and physical wear, these storage systems maintain their integrity over time while supporting consistent sanitation and workflow requirements.

Here are some of the key benefits of plastic shelving for commercial applications:

1. Rust and Corrosion-Proof

Unlike many types of metal shelving, high-performance polymers/plastics do not rust, corrode, or flake, even when exposed to corrosive substances. This is especially important in environments with high water, condensation, or chemical exposure.

Excessive moisture and certain chemicals increase the risk of coating breakdown and material degradation in painted or epoxy-coated metals, giving plastic shelving an advantage in walk-in coolers, dish areas, and other wet environments where non-stainless-steel shelving might rust.

MetroMax shelving provides a lifetime warranty against rust and corrosion.

2. Strength and Durability

As mentioned earlier, heavy-duty plastic shelving is designed for commercial applications, ensuring long-term durability and performance. Commercial-grade plastic shelving is extremely strong and durable, capable of holding hundreds of pounds per shelf.

While it’s easy to assume that metal shelving, such as chrome wire, is inherently stronger and more durable than plastic, that’s untrue. High-quality and heavy-duty plastic shelving maintains its strength over time and can hold as much weight as—if not more than—comparable wire shelving units.

3. Smooth, Easy-to-Clean Surfaces

Unlike wood shelving, plastic shelving provides a non-porous, non-shedding surface that makes cleaning and sanitation easier. Not only does the smooth surface help resist grime, but it also offers a safe way to store more delicate items, such as sterile packs, which may tear on wire shelves.

These smooth shelf mats are often removable for easy cleaning and maintenance. Additionally, many systems, such as MetroMax, have built-in Microban® antimicrobial protection to help keep the shelves cleaner between regular cleanings.

4. Modular and Adaptable Configurations

Plastic shelving offers customizable configurations for mobile, stationary, and track systems that adapt easily to your workflow. Adjustable shelves, interchangeable components, and add-on units also enable your shelving systems to change as your storage needs evolve. This flexibility helps facilities reconfigure layouts without replacing the entire shelving system.

5. Long-Term Performance in all Environments

In addition to resisting moisture without rust or corrosion, high-performance polymers withstand cold temperatures, humidity, and temperature changes. This enables plastic shelving to perform reliably in walk-in coolers, commercial freezers, dish rooms, and high-humidity storage areas without compromising product integrity.

Additionally, many heavy-duty plastic shelving units are NSF-certified for all environments, supporting industry-specific requirements in foodservice, healthcare, and laboratory facilities without requiring material changes across departments.

Plastic Shelving vs. Wire Shelving

Material is one of the most important factors when choosing the right shelving, and plastic and wire shelving are often top contenders. People want to know which is the best, thinking that one must be superior to the other. However, this is not a simple question, and it does not have a simple answer.

When considering plastic vs. wire shelving, it comes down to the application.

Both plastic and wire shelving are reliable options for commercial storage, and each performs best in different environments. The right choice will depend on several factors, including exposure to moisture and chemicals, cleanability, and how the shelving will be used day-to-day.

Structural Differences

Wire shelving features an open-grid metal structure that supports excellent airflow and visibility. Plastic shelving uses high-strength polymer frames and generally has removable shelf mats, which can be open-grid or solid. Wire offers greater ventilation, while plastic provides a smoother, more protective storage surface.

Metro Super Erecta wire shelving and MetroMax plastic shelving systems use one-piece frames and 360˚ post capture to ensure structural stability in all applications, including stationary, mobile, and high-density track shelving.

Corrosion Resistance

Wire shelving is available in several finishes suited to different applications: chrome for dry storage, epoxy for moderate humidity, and stainless steel for high-corrosion environments. Plastic shelving is naturally 100% corrosion-proof, making it a better choice for walk-ins, dish rooms, and wet or chemical-heavy areas.

Cleanability

Wire’s open design helps limit dust accumulation but may require more detailed cleaning around welds or wires. Plastic shelving has smooth, non-porous mats that are easy to wipe down or remove for deep cleaning. This makes plastic particularly well-suited to applications with strict hygiene requirements, especially because heavy-duty plastic shelves can withstand chemical and salt exposure.

Weight Capacity

Both plastic and wire shelving can support heavy commercial loads without experiencing fatigue. The specific weight capacity will depend on the load rating of each shelving unit, but the best plastic shelving systems will have weight capacities very similar to those of traditional wire shelving.

For example, both Metro Super Erecta wire shelves and MetroMax 4 plastic shelving can hold up to 800 lbs. per shelf (up to 2,000 lbs. per stationary unit). MetroMax i, which is 100% rust-proof plastic shelving reinforced with stainless steel, can hold even more weight (up to 1,000 lbs. per shelf and 2,000 lbs. per stationary unit).

Durability

High-performance plastic shelving systems are naturally rust- and corrosion-proof, making them durable in all environments, including walk-ins and sterile environments. Heavy-duty plastic can withstand temperature changes, moisture, and harsh cleaning chemicals without degrading.

For wire shelving, the material/finish affects the overall durability:

Chrome: Chrome-plated wire shelving is one of the most popular shelving designs because it’s cost-effective, easy to install, and aesthetically pleasing. It is durable in dry environments but prone to rust over time when exposed to water or chemicals.

Epoxy-coated: Epoxy-coated Metroseal wire shelving has a protective layer applied to a zinc-plated metal wire substrate, creating a durable, chip-resistant surface with good corrosion protection. Wire epoxy shelving has better moisture and chemical resistance than chrome, making it more durable for those applications.

Stainless Steel: Stainless steel shelving is among the most durable storage solutions, along with MetroMax. It's non-corrosive and highly resistant to chemicals, moisture, and bacteria. It is the preferred metal shelving option for environments that require durable shelving under harsher-than-average conditions. Type 304 and Type 316 grade stainless steel options can withstand routine exposure to high-temperature cart wash chambers and autoclave sterilization.

Material matters, but so does the shelf design. Shelving systems with integrated frames and secure, full-post engagement offer greater structural stability and better performance across mobile, stationary, and heavy-duty applications, whether predominantly metal or plastic shelves.

Environmental Suitability

- Wire (chrome): Dry storage, general stockrooms

- Wire (epoxy): Walk-ins, cooler environments, moderate humidity

- Wire (stainless steel): All environments, including high humidity, corrosive environments, and hygienic applications

- Plastic shelving: All environments, including wet, cold, chemical, or hygienic applications

Please note: plastic shelving is not suitable for extreme freezer conditions within the pharmaceutical industry or autoclave high-temperature sterilization processes. Stainless steel shelving should be used in such applications.

When to Choose Plastic Shelving

Plastic shelving is suitable for use in all environments, including dry storage, but here are some specific applications that make the most sense for choosing heavy-duty plastic shelving like MetroMax:

- Storage areas with frequent or continuous exposure to moisture, salt, or sanitizing chemicals, including humidity

- Walk-ins, freezers, dish rooms, and other wet environments

- Environmental chambers

- Sterile storage requiring smooth, protective surfaces, such as SPDs

- Chemical storage areas

- Clean environments (stainless steel alternative)

When to Choose Wire Shelving

The best applications for wire shelving will vary depending on the material and finish, but here are some of the most common applications for choosing wire shelving:

- Dry storage areas needing airflow and high visibility

- Rooms where adjustability and reconfiguration are frequent (compatible with Metro EZ-ADD shelves)

- Applications requiring slanted or specialty shelf types

- Lab/cleanroom applications specifying stainless steel (such as pharmaceutical freezers and high-temp sanitization processes)

Key Considerations for Plastic Shelving

Commercial environments place strict demands on storage equipment, and not all plastic shelving is engineered to perform under those conditions. When evaluating shelving systems for foodservice, healthcare, laboratory, cold storage, or general commercial use, the factors help to distinguish heavy-duty systems from lighter consumer options.

Material Quality and Construction

Commercial-grade plastic shelving should be constructed from high-strength, advanced polymers rather than thin molded plastic (think heavy-duty commercial storage vs. residential garage shelving). Reinforced structural components are also key to ensuring the unit can withstand heavy commercial use.

Look for solid shelf frames, reinforced corners, and durable materials that resist cracking, sagging, and chemical degradation. These attributes will help ensure your shelving remains stable and maintains its load capacity over time.

Reliable Weight Capacity

Heavy-duty polymer shelving should support substantial commercial loads, and its weight ratings should remain consistent throughout the product's life. Avoid plastic shelving systems that rely on snap-together joints or lightweight plastic frames, as they can fatigue and crack/collapse over time. Shelves built with reinforced polymer and stable post engagement (such as MetroMax) offer the most reliable long-term performance.

Structural Stability

The connection between the shelves and posts is a key indicator of overall quality and longevity. Full-post engagement, reinforced corners, and rigid shelf frames prevent wobbling and provide stable performance under daily use, especially in mobile applications. Systems held together by simple plastic tabs or friction-fit joints are prone to shifting, especially when loaded heavily or moved.

Each Metro shelving unit is backed by a 100% Money-Back Guarantee against unit collapse when assembly and use conditions are met.

NSF Certification and Regulatory Compliance

Many industries, particularly foodservice, healthcare, and laboratory environments, require equipment that meets specific sanitation or regulatory standards. NSF certification is one such example.

NSF International develops public health and safety standards for products that come into contact with food, water, and other sensitive materials, including storage systems. NSF-certified shelving has undergone rigorous testing and meets specific safety, quality, and performance standards.

Keep in mind that shelving can be NSF-listed for all environments or only for dry environments. Shelving certified for all environments (including refrigerators, freezers, and ware washing areas) has met additional testing requirements, including corrosion resistance testing. If using plastic shelving in regulated environments, ensure it meets regulatory requirements, including but not limited to NSF certification.

Types of Plastic Shelving Systems

Heavy-duty plastic shelving is available in numerous configurations to support different storage needs across all industries and applications. Whether you’re looking for stable, long-term shelving, mobile-friendly storage carts, or high-density solutions, plastic shelving is adaptable to fit a wide range of commercial applications and workflows.

Stationary Plastic Shelving

Stationary shelving, also called static shelving, is the most common configuration for long-term, high-capacity storage and is often the first thing that comes to mind when people think of shelving. These units provide maximum stability and are ideal for applications where shelving does not need to move frequently.

The only downside of stationary plastic shelving units is that moving them is more difficult because they lack the wheels that mobile shelving has.

Common uses for static plastic shelving include:

- Bulk food storage

- Medical supply areas

- Laboratory consumables

- Retail backrooms

- Cold storage and freezer applications

- Warehouse storage

Mobile Plastic Shelving

Mobile plastic shelving offers the same durability and corrosion resistance as stationary systems while adding flexibility. These units are equipped with casters, making them easy to maneuver during cleaning, restocking, or reorganization. Locking casters allow you to secure them in place for long-term storage.

Because polymer shelves resist moisture, chemicals, and cleaning agents, they are ideal for environments that require frequent wash-downs or where mobility improves workflow. Caster materials and diameter influence weight capacity and maneuverability, so selecting the right caster type is important for high-load applications.

The only downside of mobile plastic shelving is that mobile units typically have a lower overall load rating than stationary units because of their casters.

Common uses for mobile plastic shelving include:

- Central Sterile Processing Departments

- Dish room drying and storage

- Walk-in cooler and freezer storage

- Grocery and foodservice prep areas

- Back of house storage

- General supply storage

High-Density Plastic Shelving

High-density track shelving increases storage capacity up to 50% without adding additional floor space. High-density shelving systems feature sliding mobile units between stationary end units, creating active aisles for increased storage capacity and easy access.

MetroMax plastic shelving can be used with Metro Top-Track (overhead track) and qwikTRAK (floor-track) systems to create corrosion-proof, high-density storage that performs well in wet, cold, or space-restricted environments.

Common uses for plastic high-density shelving include:

- Walk-in coolers and freezers

- Sterile processing departments

- Laboratories

- Pharmacy and medication storage

- Back-of-house storage areas with limited floor space

- Environmental rooms

Plastic Dunnage Shelving and Racks

Plastic dunnage racks elevate heavy materials off the floor, protecting them from moisture, condensation, and contamination. Dunnage racks are designed to handle heavier loads than standard shelving and are commonly used to store bulk items, large containers, or equipment that should not sit directly on the ground.

Polymer dunnage racks offer several advantages over metal alternatives, including complete corrosion resistance and easy cleanability.

Common uses for plastic dunnage shelves include:

- Food bulk storage

- Cold rooms and freezers

- Industrial and warehouse environments

- Healthcare and lab supply zones that require cleaning underneath stored items

- Breweries

Plastic Wall Shelving

Wall-mounted shelving adds more storage capacity without taking up valuable floor space. This type of storage system is ideal for areas where workflow, sanitation, or square-footage constraints make traditional shelving units impractical.

Metro SmartWall Life combines stainless steel (304 or 316) and MetroMax shelves to create a vertical storage solution ideal for environments that demand long-term durability and frequent sanitation, including kitchens, labs, and healthcare facilities.

Common uses for plastic wall shelves include:

- Foodservice prep and handwash stations

- Dish room and ware washing areas

- Chemical storage

- Above dunnage racks

- Labs and cleanroom supply

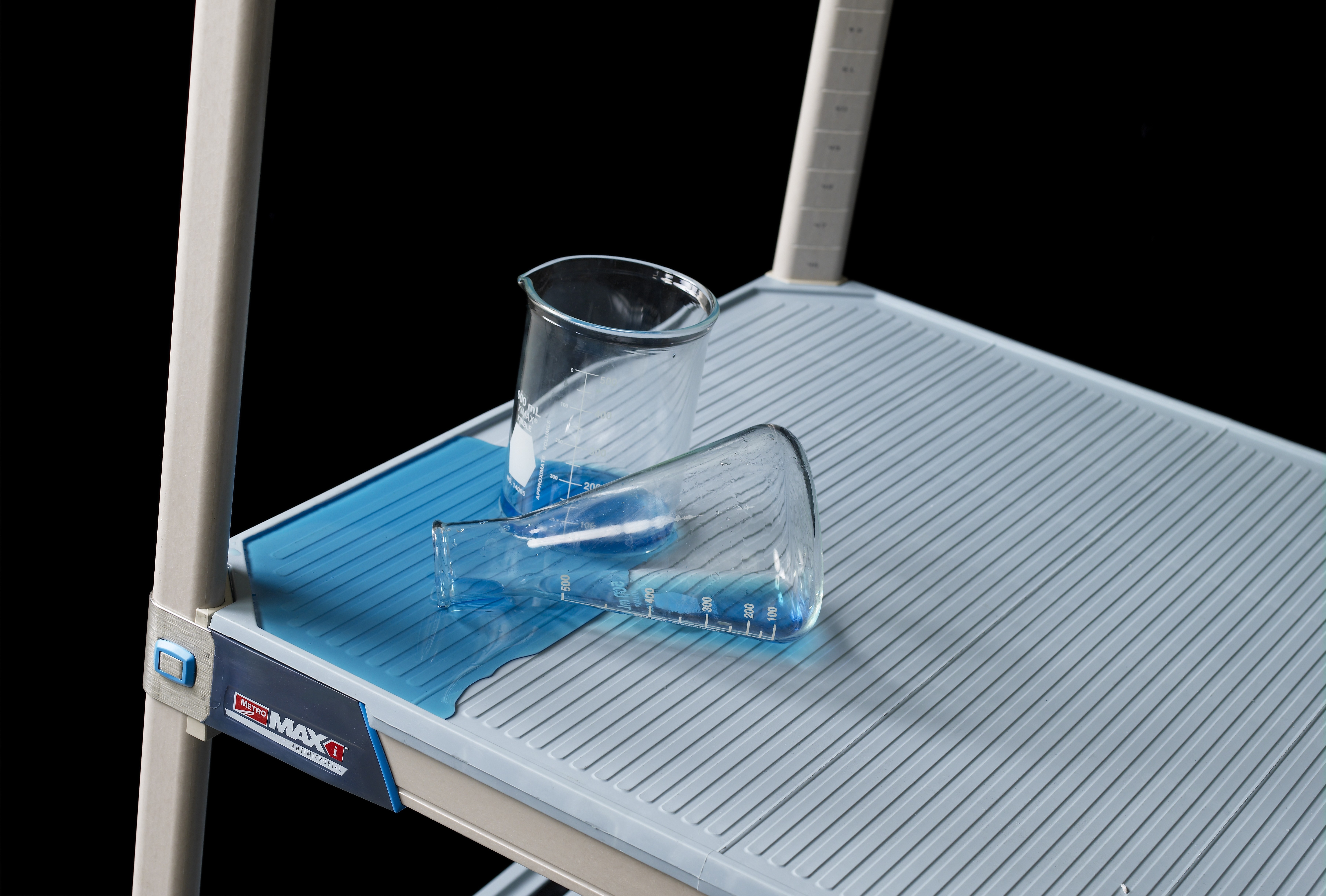

Plastic Drying Racks

Plastic drying racks provide a hygienic, corrosion-proof solution for air-drying kitchenware, utensils, containers, and lab equipment. They are specifically designed for wet environments where constant exposure to water, detergents, and sanitizers can cause metal shelving to deteriorate over time. Polymer shelves eliminate the risk of rust and peeling finishes while offering smooth, non-porous surfaces that help support sanitation requirements.

Plastic drying racks provide a hygienic, corrosion-proof solution for air-drying kitchenware, utensils, containers, and lab equipment. They are specifically designed for wet environments where constant exposure to water, detergents, and sanitizers can cause metal shelving to deteriorate over time. Polymer shelves eliminate the risk of rust and peeling finishes while offering smooth, non-porous surfaces that help support sanitation requirements.

Drying rack configurations often use open-grid polymer mats to promote drainage and airflow, thereby speeding drying time and reducing moisture buildup. MetroMax drying solutions integrate seamlessly with existing MetroMax units or function as standalone stations, depending on workflow needs.

Common uses for plastic commercial drying racks include:

- Commercial kitchens and dish rooms

- Healthcare environments with reprocessing tasks

- Laboratory glassware drying

- Beverage and bar service areas

- Any wet zone requiring hygienic air-drying capabilities

MetroMax Heavy-Duty Plastic Shelving Systems

MetroMax is Metro’s brand of heavy-duty plastic shelving designed for commercial storage applications, providing a high-performance alternative to metal shelving in demanding environments.

All MetroMax plastic racks feature wraparound corners and durable one-piece shelf frames, a design that helps evenly distribute weight and maintain stability under load. These systems are commonly specified where corrosion resistance, cleanability, and long-term performance are important considerations.

Several core design elements are consistent across all MetroMax shelving options:

- Plastic (polymer) shelf mats that are smooth, non-porous, and removable for cleaning and maintenance

- Built-in Microban® antimicrobial protection to help keep shelf surfaces cleaner between cleanings

- One-piece shelf frames with full 360-degree post capture for structural stability

- Modular configuration options for stationary, mobile, or high-density layouts (including track systems like Top-Track® and qwikTRAK®)

- NSF certification for use in regulated environments

- Coverage under Metro’s Never Collapse Guarantee

Together, these shared characteristics allow all MetroMax plastic shelving to perform reliably in high-performance environments, including areas exposed to moisture, frequent cleaning, or harsh chemicals.

MetroMax is available in three distinct constructions to support different load requirements and adjustment needs: fully plastic shelving, plastic shelving with stainless steel reinforcement, and a hybrid option that combines plastic shelf mats with an epoxy-coated wire frame.

The sections below provide an overview of each system and explain how they differ.

MetroMax 4: All-Plastic Shelving

MetroMax 4 is an all-plastic shelving system designed to provide rust-proof storage for standard commercial loads. Built entirely from high-strength polymers, it offers many of the same benefits as traditional wire shelving while eliminating concerns related to rust, flaking, or coating breakdown in wet or high-humidity environments.

Because of its balance of durability, versatility, and value, MetroMax 4 is often selected as a general-purpose plastic shelving solution across a wide range of industries.

Key characteristics of MetroMax 4 plastic shelving:

- Fully polymer construction with no exposed metal components

- Load capacity of up to 800 lbs. per shelf and 2,000 lbs. per stationary unit

- Removable polymer shelf mats available in solid or open-grid styles

- Corrosion-proof performance suitable for wet, cold, or frequently cleaned areas

- Lifetime warranty against rust and corrosion

MetroMax i: All-Plastic Shelving with Stainless Steel

MetroMax i is the most durable and versatile option within the MetroMax line. It combines polymer shelving with stainless-steel corner reinforcements to support heavier loads while maintaining corrosion resistance.

This construction allows MetroMax i to serve as a stainless-steel shelving alternative in applications where strength, stability, and resistance to moisture or chemical degradation are equally important.

Key characteristics of MetroMax i plastic shelving:

- Polymer shelves reinforced with stainless steel corners for added strength

- Load capacity of up to 1,000 lbs. per shelf and 2,000 lbs. per stationary unit

- Removable shelf mats are available in open-grid and solid-mat styles. Solid mats on models 60” and shorter are one continuous piece and offer the best spill containment MetroMax option.

- Optional dunnage shelving with higher weight capacities

- Fully corrosion-proof design suitable for harsh or highly regulated environments

- Lifetime warranty against rust and corrosion

MetroMax i is often preferred in healthcare facilities, laboratories, sterile processing departments, and other settings where heavier loads are involved.

MetroMax Q: Hybrid Plastic and Wire Shelving with Quick Adjustment

MetroMax Q is a hybrid shelving system that combines polymer shelf mats with an epoxy-coated wire support frame. It is designed for environments where storage layouts change frequently, and shelves need to be adjusted quickly and easily.

Unlike fully polymer MetroMax systems, MetroMax Q uses a wire substructure to support Metro’s quick-adjust design, allowing shelf levels to be repositioned without tools.

Key characteristics of MetroMax Q hybrid shelving:

- Polymer shelf mats supported by an epoxy-coated wire frame

- Quick-adjust shelving that allows fast shelf height changes

- Load capacity of up to 800 lbs. per shelf and 2,000 lbs. per stationary unit

- Corrosion-resistant construction with a 25-year rust and corrosion warranty

- Grid-style shelf mats promote airflow in humid environments

MetroMax Q is often selected for foodservice, retail back-of-house storage, and other commercial applications where flexibility and frequent reconfiguration are important considerations.

Applications for Heavy-Duty Plastic Shelving

One of the biggest benefits of heavy-duty plastic shelving is its suitability for most applications across industries, from food service and retail to healthcare and industrial settings. However, the specific reasons for choosing this type of shelving generally include operational demands, environmental conditions, regulatory requirements, and even cost.

Here are some of the many industries where plastic shelving is commonly specified, along with the types of storage areas where it is most often used.

Foodservice & Hospitality

Foodservice environments involve constant exposure to moisture, frequent cleaning, and temperature variations between dry storage, refrigerated areas, and dishrooms. Storage systems in these spaces must perform reliably under daily washdowns while supporting food safety and sanitation standards.

Plastic shelving is commonly used in the following foodservice applications:

- Walk-in cooler and freezer shelving

- Dishwashing rooms and wet prep areas

- Dry storage for packaged ingredients

- Back-of-house kitchen storage

Because many foodservice facilities include a mix of wet, cold, and dry environments, plastic shelving is often used to maintain consistent performance without concerns about rust or coating degradation over time.

Additionally, plastic shelving like MetroMax is NSF-certified for use in all environments.

Grocery and Retail Operations

Grocery and retail facilities typically include a mix of dry storage, refrigerated storage, and receiving areas. Shelving must perform consistently across varying humidity levels while supporting frequent restocking and inventory turnover.

Plastic shelving is often used in the following retail and grocery applications:

- Grocery backrooms and stockrooms

- Refrigerated and cold storage areas

- Receiving and staging zones

Its ability to perform across multiple storage conditions within the same facility makes plastic shelving a practical choice for retail operations managing diverse inventory needs.

Healthcare and Medical Facilities

Healthcare storage environments place a strong emphasis on cleanliness, organization, and protection of sensitive supplies. In areas that support infection control or sterile workflows, shelving materials must be easy to clean and compatible with healthcare sanitation protocols.

Plastic shelving is frequently used in the following healthcare applications:

- Sterile Processing Departments (SPDs)

- Clean supply and central supply rooms

- Clinical storage areas

- Medication and support storage

Smooth, non-porous shelf surfaces are especially important in these environments to help protect wrapped instruments, sterile packs, and other delicate medical items from damage.

Learn more about the benefits of plastic shelving in SPDs.

Laboratories and Clean Environments

Labs and cleanrooms often involve chemical exposure, controlled conditions, and regular cleaning with specialized agents. Storage systems in these areas must maintain structural integrity without reacting to chemicals or degrading over time.

Plastic shelving is commonly used in the following laboratory applications:

- General laboratory storage

- Chemical storage areas

- Environmental chambers

- Cleanroom-adjacent spaces

In these settings, material compatibility and cleanability are as important as load capacity. Consider heavy-duty plastic shelving, such as MetroMax i, as an alternative to stainless-steel shelving in these environments.

Industrial and General Commercial Storage

Industrial and commercial storage areas may be exposed to heavier loads, cleaning chemicals, or non-climate-controlled conditions. Storage systems in these environments must remain stable and reliable over long periods of use.

Plastic shelving is used in industrial and commercial applications such as:

- Chemical storage areas

- Maintenance and utility rooms

- Manufacturing support storage

- General commercial stockrooms

In these settings, long-term durability and resistance to environmental stress are often key considerations.

Upgrade Your Storage with MetroMax Heavy-Duty Plastic Shelving

Whether you’re planning a new storage space or upgrading an existing one, heavy-duty plastic shelving offers long-term performance in environments where cleanliness, corrosion resistance, and durability matter most.

MetroMax plastic shelving is designed to meet those demands across foodservice, healthcare, laboratory, and other commercial applications, with flexible configurations that adapt as storage needs change.

Metro offers the tools, configurations, and expert support to help you design a MetroMax shelving system that fits your space and application.

To get started, contact Metro or connect with your local Metro representative.

Frequently Asked Questions About Plastic Shelving

Still have questions about MetroMax heavy-duty plastic shelving? Here are answers to some of the most asked questions about rust-proof commercial shelving:

What is the difference between plastic shelving and wire shelving?

The biggest difference between plastic shelving and wire shelving is the material and how each performs in different environments. Wire shelving is most often made of steel, which can rust if exposed to certain environmental conditions, such as moisture. Plastic shelving, on the other hand, will not rust or corrode in such conditions, which is why it is often the preferred choice for wet, cold, or highly sanitized spaces.

Is plastic shelving strong enough for commercial use?

Yes. Commercial-grade plastic shelving is engineered to support heavy loads and long-term use. Many heavy-duty plastic shelving systems have load ratings comparable to or higher than those of traditional wire shelving. Strength depends on the specific construction of the shelving system, including the shelf frame, post design, and materials used. Always confirm the load rating and ensure the units are properly assembled before use.

Can plastic shelving be used in walk-in coolers and freezers?

Plastic shelving is among the best storage solutions for walk-in coolers and freezers because it performs well in cold, high-humidity environments. Unlike some metal shelving (such as chrome wire), plastic shelving will not rust, flake, or degrade when exposed to condensation or temperature fluctuations, making it a reliable option for refrigerated storage.

Is plastic shelving NSF certified?

Many commercial plastic shelving systems, including MetroMax, are NSF certified for use in regulated environments. NSF certification indicates that the shelving meets standards for food safety, sanitation, and cleanability. Shelving can be NSF-certified for all environments or dry environments only.

Does plastic shelving require special cleaning or maintenance?

Plastic shelving is generally easy to clean and maintain. Smooth shelf surfaces can be wiped down with standard cleaning agents, and removable shelf mats allow for deeper cleaning when needed. Some systems, such as MetroMax, also include antimicrobial protection to help keep surfaces cleaner between routine cleanings.