For hospitals and surgery centers, sterile processing departments (SPDs) are critical in ensuring patient safety. Cleaning and sterilizing soiled surgical instruments and medical devices is one of the most essential functions of patient care, making SPDs among the most critical departments within a hospital.

The need for sterilization is constant: without sterilized equipment, hospitals and surgical facilities would be unable to perform procedures. SPDs ensure facilities can keep up with the demand for operations and remain in compliance with government regulations and CDC guidelines.

However, despite the ever-growing importance of sterile processing, insufficient storage space is a universal problem among healthcare facilities, particularly within central sterile services departments. That’s where Metro comes in: we offer solutions such as high-density shelving to help combat some of the biggest challenges facing SPDs today.

The Current Challenges of SPDs

While the SPD is the backbone of a functioning surgical suite, they are not immune to challenges. And because cleaning, sterilizing, and storing surgical instruments is so critical, overcoming these challenges is of the utmost importance.

Here are three of the biggest issues facing sterile processing departments today:

1. Limited Storage Space

Healthcare facilities are constantly under pressure to optimize space utilization. Unfortunately, available storage and growth plans aren’t always aligned, so sterile processing storage areas can become too small when processes change, or new equipment and/or procedures are introduced.

2. Access and Workflow

SPDs must have enough room to store items, and sterilized tools/equipment must also be readily accessible. Overly packed shelves or inconvenient layouts can slow retrieval processes and the overall workflow, impacting surgical wait times.

3. Shelf-life of Sterile Items

The shelf life of sterile equipment is directly tied to the quality of its packaging. When items are not handled or stored correctly, they become contaminated, which means they must be re-processed. This costly and time-consuming error can affect the OR schedule and patient safety if proper storage and handling procedures are not followed.

While each issue presents its own challenges for healthcare facilities, efficient storage solutions can alleviate these issues.

Overcoming Limited Storage Space with High-Density Shelving

All sterile products must be maintained and stored to maintain sterility until used. Until an item is transported (such as via a surgical case cart), it will likely spend most of its time in the facility’s sterile storage area(s). Therefore, all storage practices and procedures must be designed to maintain sterility.

In an ideal situation, the sterile storage areas within the hospital would be large and organized with ample shelving. In practice, however, we rarely find this to be true; more often than not, facilities are dealing with cramped storage space, leading to poor organization and increased risk of damage or contamination. Improper storage can also lead to adverse patient outcomes, potential loss of accreditation, and hefty penalties and fines.

One of the biggest steps you can take to ensure your SPD is set up for success is to provide sufficient storage solutions. If you’re looking to overcome your already limited storage space, one of the best solutions is high-density shelving.

Metro Track Shelving Solutions

High-density shelving solutions can significantly increase your storage capacity, allowing you to incorporate more shelving in a smaller footprint. For some spaces, track shelving has enabled facilities to increase their storage capacity by as much as 50% without adding additional floor space. And for a busy department such as sterile processing, every inch matters.

Track shelving is designed to accommodate more physical units in limited spaces, such as SPDs. Metro’s high-density shelving features sliding mobile units between stationary end units to create active aisles, allowing you to store more in the same area while keeping supplies accessible. The high-density moveable aisle design allows staff to store the sterile packs and create an organized area for carts and other equipment.

At Metro, we offer high-density shelving options that utilize an overhead or floor track. Both types of track shelving are also compatible with wire, plastic, and hybrid shelving units. However, for use in an SPD, we recommend MetroMax i polymer shelving, which offers better protection for sterile packs and wrapped trays.

Metro's Top-Track High-Density Storage Systems

Top-Track features an overhead guide track that aligns the sliding mobile units while the floor area remains free of obstacles. Since Top-Track is above the shelving and not on the floor, it offers convenient access to the storage aisle and makes routine cleaning easier.

Metro’s qwikTRAK High-Density Storage System

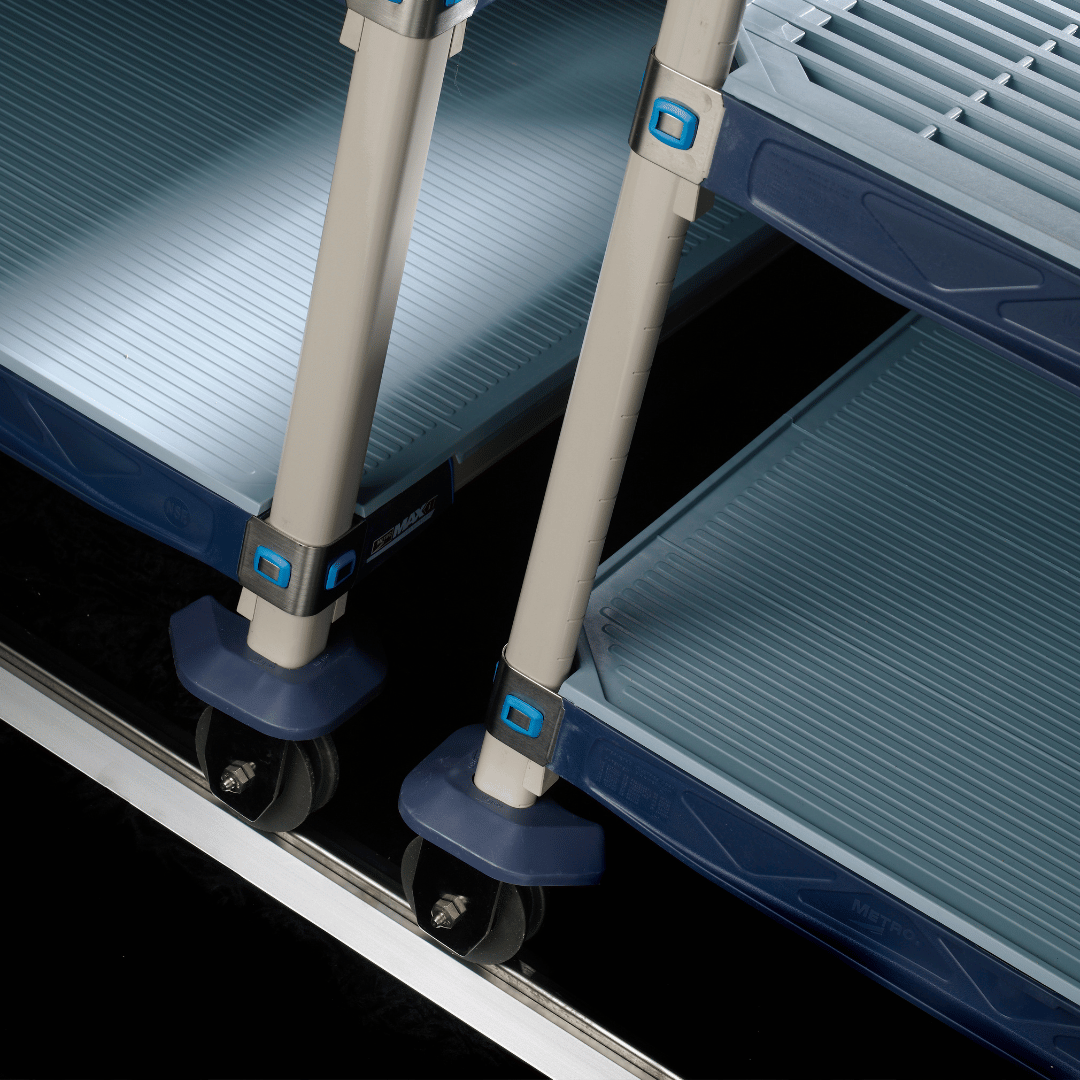

qwikTRAK uses a conventional floor track to guide the mobile shelving units. The track also compensates for rough or choppy floors, enabling the mobile shelving units to glide easily on heavy-duty casters.

Is a Track Shelving System Right for Your Sterile Processing Department?

High-density track shelving is a great way to improve the storage capacity for facilities facing space constraints. But is it the right fit for your SPD? Here is a quick breakdown to help you decide whether to add high-density storage to your sterile processing areas.

Benefits of Metro High-Density Track Shelving

- Maximize Storage Capacity: The active aisle's design allows you to incorporate more shelving units within a confined space, increasing potential capacity by up to 50%.

- Improved Organization: The increased space allows staff to store sterilized packages correctly, which makes it easier to find items and review inventory quickly.

- Scalability: Adding high-density track shelving future-proofs your sterile storage, providing more space as your department grows.

- Maintain Integrity of Sterilized Items: MetroMax polymer track shelving is easier to clean and provides a safer design for sterile packs (compared to wire shelving alternatives).

Considerations for Track Shelving Systems

- Workflow Integration: While track shelving offers increased capacity, accessing supplies requires moving the mobile units. Assess your workflow and identify frequently used items that might need to be readily accessible on standalone polymer shelving units for optimal efficiency.

- Space Requirements: Track shelving significantly increases storage density; however, they need a minimum footprint to be effective and follow sterile storage standards.

The Verdict

High-density track shelving systems like Top-Track and qwikTRAK are effective solutions for healthcare facilities looking to increase the storage potential of their sterile processing department. However, a successful implementation requires careful consideration of your specific workflow needs and space constraints.

Fortunately, your Metro rep can help you evaluate your current storage challenges and future growth projections and determine whether a track shelving system is the best solution for your storage needs.

Future-Proof Your SPD with Metro’s High-Density Storage Solutions

Predicting the future can be very challenging. Even if your conventional layout can address your current storage needs, it may not offer enough storage capacity for future growth.

Limited storage in your sterile processing department can significantly hinder your efficiency and ability to grow. It can also lead to mishandled sterile packages, costly reprocessing, delayed surgeries, and potential citations. Therefore, ensuring you are following the best storage practices for sterile tools and equipment is key—now and in the future.

At Metro, we believe in future-proofing your storage solutions. Our track shelving systems are ideal for SPDs, for both sterile instrument storage as well as clean supply storage, because they maximize storage capacity, ensuring your department can absorb the future growth of procedures within the hospital. Our storage solutions are efficient, secure, and aesthetically pleasing and can adapt to meet your individual needs.

Metro’s storage solutions are also supported by local Metro reps, who offer consultations based on their many years of experience outfitting SPDs. They can also provide onsite consultations to take measurements and provide detailed drawings of how the final solution will look in your space.

Looking for the right solution to combat the lack of space in your SPD or a one-stop shop for all your shelving, medical cart, and workstation needs? Visit our website to view our innumerable options or contact us with any questions you might have.